Extending Lathe Capacity

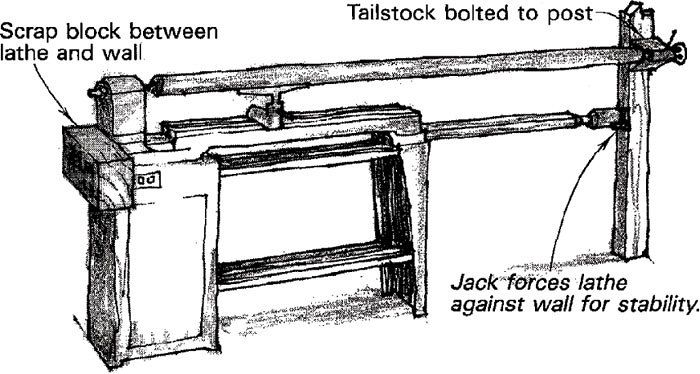

Here’s how I extended the bed capacity of my lathe. First I bolted the tailstock to a support post in my shop. To make sure the tailstock was level with and in line with the headstock, I ran a chalkline and a line level between the two. To keep the lathe in position, I used a hydraulic cylinder to force the lathe’s base against the wall a spare Lally column would work nearly as well. A piece of scrapwood protects the lathe where it presses against the wall.

For slightly shorter stock, you could shim the lathe out farther from the wall, or dispense with the jack by bolting the lathe to the floor where you need it. I did half the turning and then flipped the workpiece to finish, so I could use my regular tool rest. If you have a freestanding tool rest, you can do the work all in one shot.

D. Mayerson, Berkeley, Calif.

Fine Woodworking Magazine, February 1984 No. 50

Fine Woodworking Recommended Products

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Rockler Dust Right 650 CFM

Log in or create an account to post a comment.

Sign up Log in