Gluing Laminated Curves With Screw Blocks

Here is a method for gluing up laminated curved components that eliminates the need for large numbers of expensive clamps. By using simple hardwood clamping blocks and drywall screws, you can get all of the clamping pressure you need.

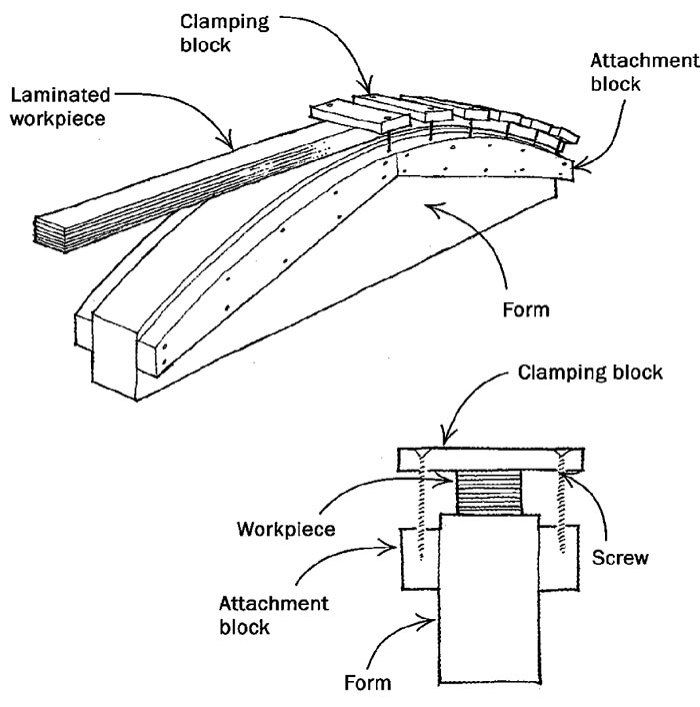

First, you’ll need to make a curved form for the laminated workpiece. The form should be just a bit wider than the workpiece. Then make screw-attachment blocks for both sides of the form, using construction-grade 2x lumber cut roughly to the shape of the curve. Screw the attachment blocks to the outsides of the form, recessing the curved edges slightly, as shown above.

Next, cut a few dozen 3/4-in.-thick hardwood clamping blocks long enough to span the full width of the form, including the attachment blocks. Drill pilot holes for screws about 1 in. from each end of the clamping blocks.

After a dry run, spread glue on each of the lamination plies and stack them together on the form. Place an extra (unglued) ply on top to help spread the clamping pressure and to prevent marring the workpiece. Starting at the center of the form, screw the clamping blocks in place, perpendicular to the curved plies. Space the blocks about every 2 in., more or less, depending on the radius of the curve. You can adapt this same basic concept to laminate inside curves or to add edge-banding to irregular contours.

David Gilmore, Maple Ridge, B.C., Canada

Fine Woodworking Magazine, December 2001 No. 152

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

MicroJig Matchfit dovetail clamps

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in