Hole-Cutter for Speaker Enclosures

I have been involved in making professional sound equipment and speaker enclosures for a number of years. The usual construction routine requires me to cut holes up to 18 in. in diameter for speaker baffles. Here’s how I use a modified router table to cut the holes accurately, quickly and safely.

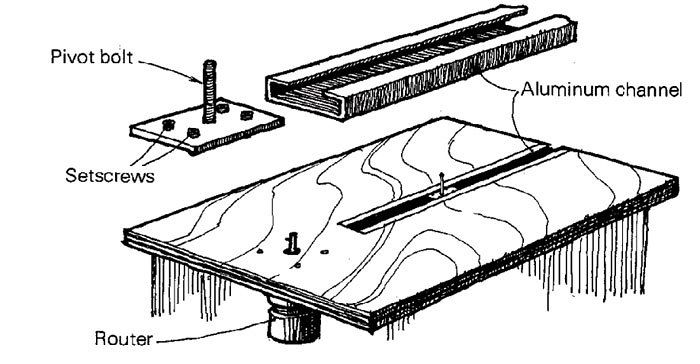

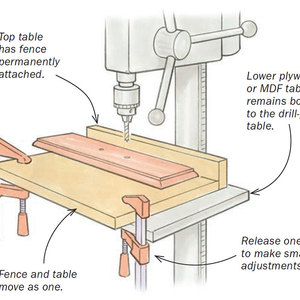

My router table is constructed of 5/8-in. Baltic birch plywood. I’ve installed an aluminum-channel track and pivot assembly on the centerline of the table as shown in the sketch. The standard 1-1/2-HP Makita router bolted underneath the table is equipped with a stagger-tooth cut-out bit (Wisconsin Knife Works #68802).

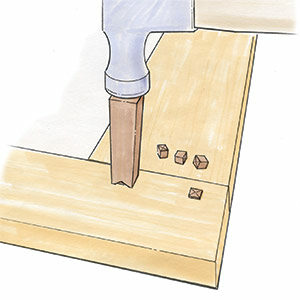

To cut a circle on the setup I first slide the pivot assembly to the right position for the radius I want. Then I lock the assembly in place by tightening the four setscrews. Next I drill a center-hole in the baffle board and slide this over the pivot assembly’s threaded rod. I secure the baffle board with a flat washer and a self-locking nut. The baffle board should rotate on the pivot with a mild resistance. Next I turn on the router, bring it up through the wood and rotate the baffle clockwise on its pivot point to cut a perfect circle. Once the device is set, you can quickly reproduce duplicate baffles.

James Campbell, Orange, Calif.

Fine Woodworking Magazine, February 1982 No. 32

Fine Woodworking Recommended Products

Woodriver Circle Cutting Jig

Hedgehog featherboards

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in