Homebuilt Outboard Lathe

Turning circular tabletops on my regular lathe was less than satisfactory. The outboard spindle was just not designed for large, unbalanced, rough work. When a friend offered me a rear wheel and axle bearing from a front-wheel-drive car (G.M. No. 1-7466906), my ideas for a special homebuilt outboard lathe came together. I figured that if the hub could handle a car wheel, it would be ideal for turning a tabletop.

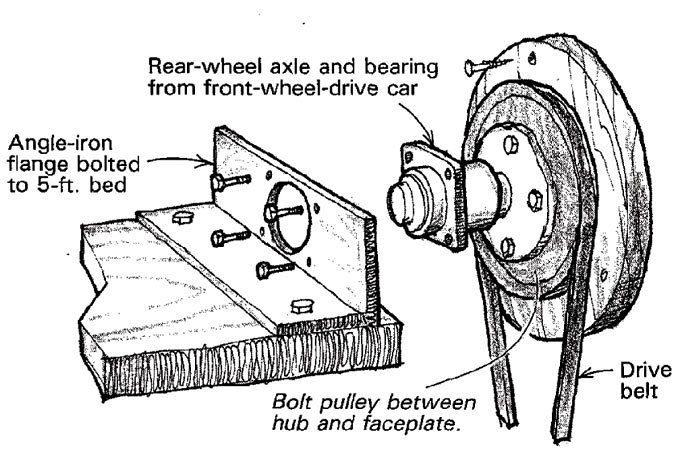

I bolted the wheel assembly’s brake flange to a 12-in. long section of 1/4-in. thick, 3×3 angle iron as shown, and lag-screwed this to a rigid yellow-pine bed about 5 ft. long.

The lathe faceplate is a 1-in. thick, 11-in. dia. oak disc. I bolted the faceplate directly to the hub with a 9-in. pulley sandwiched between. The headstock/pulley assembly is permanent, and after installation the faceplate should be trued round and faced flat. To power the lathe, I mounted a 1/2-HP, 1725-RPM motor with a 2-in. drive pulley.

The easiest way to fasten the work to the lathe headstock is to drive screws through the rim from the back side. Of course, more elaborate faceplate-fastening techniques can be designed for special projects if needed. Even on the first project, the lathe exceeded my expectations with its quiet, vibration-free performance.

Lawrence Wachenheim, Quincy, Ill.

Fine Woodworking Magazine, October 1984 No. 48

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Bessey EKH Trigger Clamps

Log in or create an account to post a comment.

Sign up Log in