Craftsman - Laser-Guided Drill Press No. 229250

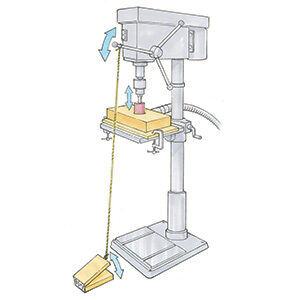

Craftsman’s 15 in. drill press features a laser guide and rack-and-pinion table lift.

Sears/Craftsman has introduced a new 15-in. drill press with a unique feature. It uses laser technology—Craftsman calls it Laser-Trac—to shoot a pair of lines that intersect with the centerline of the chuck.

The laser system is turned on and off with the flip of a switch. Two AA batteries provide the power. To use Laser-Trac, first mark the centerpoint of a hole on the workpiece. Then simply align the mark with the intersecting laser lines and drill the hole.

Curious to find out how well Laser-Trac worked, I gave the drill press, Craftsman model 229250, a good workout in the Fine Woodworking shop. At the end of the day, I concluded the laser system has both pluses and minuses.

On the plus side, the laser worked well with short bits (about 2 in. or less) with small diameters (about 1/4 in. or less). The short bits allowed me to drill with the workpiece relatively close to the chuck. The minuses were revealed when I used long bits or any bits with large diameters. Such bits partially blocked the path of the beams. As a result, the intersecting laser lines didn’t show up on the workpiece unless it was positioned well below the bit. Because the quill then had to travel farther than normal to drill a hole, I had to reach back to grab a second or sometimes even a third crank handle to lower the quill the extra distance a process that often can be awkward.

Another point here: The laser lines were not perfectly sharp, making it difficult to consistently and precisely align the mark on the workpiece with the intersecting laser lines. In addition, as the workpiece moved farther from the bit, the lines became wider and even less sharp. That said, however, the test holes I drilled were rarely off by more than 1/32 in.

So is the laser guide worth having? If you drill a lot of small holes that don’t need to be dead-on every time, I think you’d find the Laser-Trac feature helpful. But if you regularly use long or large-diameter bits, the laser guide won’t offer much help.

The drill press itself proved to be a serviceable machine. Its 5/8-in. chuck operated reasonably smoothly. Runout measured 0.004 in., compared to an average of 0.005 in. when we tested nine 15-in. to 17-in. drill presses. The rack-and-pinion table lift worked comfortably, thanks in part to soft, molded handles.

Belt changing was easy enough, allowing 12 different speeds, ranging from 250 rpm to 3,100 rpm. The quill lock and depth stops worked effectively, and the handles can be repositioned to the left of the machine, a nod to all us southpaws.

Using a 3/4-in.-dia. Forstner bit, I was able to drill 1-in.-deep holes without any sign of the belts slipping or the 120v, 8-amp motor bogging down. I also was able to drill a 1-in.-deep hole with a 2-in.-dia. Forstner bit, but I had to slow the feed rate slightly to prevent the motor from stalling.

Fine Woodworking Recommended Products

DeWalt 735X Planer

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in