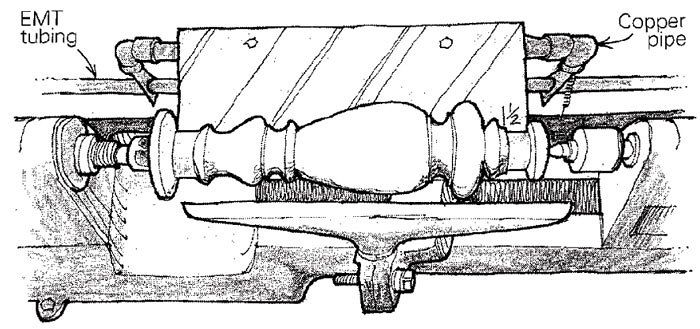

Lathe Template Fixture

A few months ago, while teaching lathe duplication methods to my cabinetmaking class, I discovered a novel and efficient method of rapidly producing identical turnings. Mount a template of 16-ga. metal on a swinging arm at the back of the lathe. After the stock has been turned round, swing the template against it with a light spring, maintaining enough tension to prevent excessive bounce. By cutting from the front in normal fashion and referring visually to the template at the rear, you will be able to quickly and accurately produce any number of identical turnings with few rejects and a minimum of tedious measuring and calipering.

To keep each turning the same diameter, scratch a final diameter reference on a short, straight run at each end of the template. Work each end of the turning to these reference diameters first, then the gap between the reference diameters and the template will show the maximum cut depth to be taken from the workpiece’s high spot.

My version of the duplicator is made from 3/4-in. copper pipe, copper pipe elbows and a length of 1/2-in. EMT conduit. Solder up a U-shaped assembly from the copper pipe, flatten the pipe on each of the U’s legs and drill to pivot on the conduit. Flatten the crosspiece of the U and drill to attach the template. Adjust the angle at which the template hits the work by heating the joints of the U and turning the template to the proper position.

Doug Christie, Fort Grant, Ariz.

Fine Woodworking Magazine, October 1983 No. 42

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Woodriver Circle Cutting Jig

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in