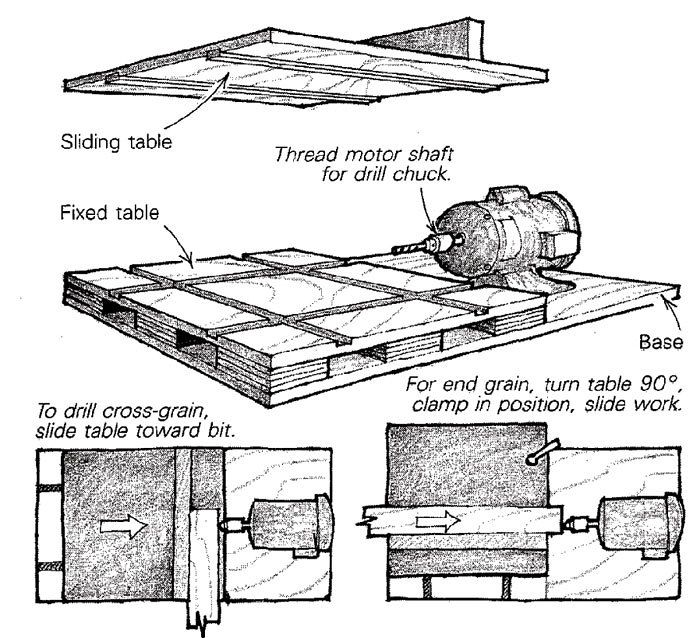

Low-Tech Horizontal Boring Machine

My home-built horizontal boring machine isn’t as sophisticated as M.G. Rekoff’s (Fine Woodworking #37), but it’s simple in design and sturdy enough to do an outstanding job. Its simplicity comes from a sliding table that moves the stock into the bit rather than vice versa.

To begin, you’ll need a 1/4-HP to 1/2-HP, 1750-RPM motor, with its shaft threaded to accept a 1/2-in. drill chuck. I made the base, the fixed table and the sliding table out of 3/4-in. Baltic birch plywood.

Cut two square pieces the same size for the fixed table and the sliding table, then make all dado cuts at the same rip-fence setting to ensure that the dadoes align. Glue and screw hardwood runners into the dadoes in the sliding table. These runners should then fit either pair of tracks in the fixed table. Next bolt down the motor assembly and the fixed table to the base. Shim the fixed table so that the sliding table will be at the proper height relative to the bit. Glue and screw a fence to the top of the sliding table.

The height of the sliding table is not adjustable in this design. This presents no hardship for me because most of my boring is in 4/4 and 5/4 stock. I shimmed the fixed height so that my machine would normally bore 5/4 stock. To switch over to 4/4 stock, I place a sheet of 1/10-in. plexiglass on top of the sliding table.

Ed Devlin, Rothsay, Minn.

Fine Woodworking Magazine, October 1983 No. 42

Fine Woodworking Recommended Products

Double Sided Tape

Suizan Japanese Pull Saw

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in