Making Large Pulleys on the Tablesaw

The large, slow-moving turntable I was commissioned to build as part of a stage set for my community’s performing-arts center presented an interesting challenge. The 4-ft. turntable had to hold a 200-lb. actor and spin at 2 RPM. Our solution was to use a low-RPM gear-reduction electric motor further reduced by a V-belt turning a 15-in.-dia. pulley. I had no problem locating the small pulley that fit on the motor shaft. But I was unable to find a 15-in.-dia. pulley locally and did not have a lathe to turn one. However, I found another, very simple method to make the pulley.

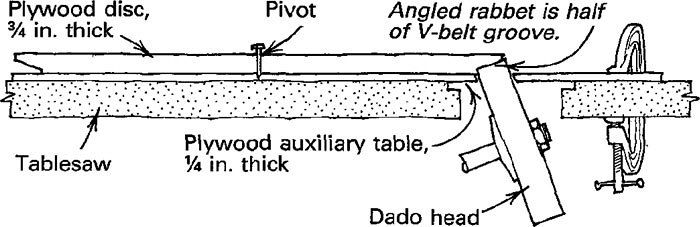

The pulley consists of two 15-in.-dia. discs, which I bandsawed from 3/4-in.-thick plywood and screwed together. But before assembling the two discs, I used a dado head on the tablesaw to cut an angled rabbet in the edge of each disc to form the groove for the V-belt. To do this, I installed the dado head on my tablesaw and tilted the arbor to the same angle as the side of the Vbelt. I clamped a piece of 1/4-in.-thick plywood to the top of my saw and drilled a small pivot hole into the plywood, 7-1/2 in. from the dado head and in line with the arbor. Then, with the dado blade lowered, I pushed a pin through the center hole of one of the discs and into the pivot hole in the plywood auxiliary table. Next, I turned the saw on and slowly rotated the plywood disc as I simultaneously slowly raised the dado blade. When the rabbet on the first disc was cut to the proper depth, I lowered the blade, removed the disc and repeated the process with the second disc. I then screwed the two discs together to form a strong, durable pulley with an accurate V-belt groove.

Gene Stemmann, Corvallis, Ore.

Fine Woodworking Magazine, April 1991 No. 87

Log in or create an account to post a comment.

Sign up Log in