Making Toy Wheels

Hardwood wheels for toys are expensive, not well sanded and do not come in many varieties of wood. I tried making my own, but the work was prohibitively time-consuming until I came up with the modified screw center I now use. With it I can turn out a wheel every four minutes on production runs.

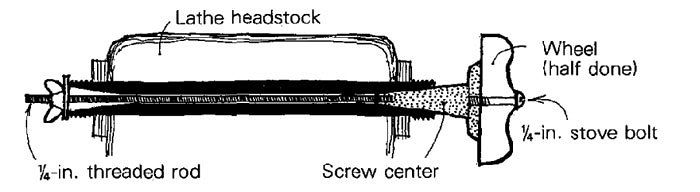

I started with a standard morse-taper screw center (Sears) that I modified in two ways. First, I drilled and tapped the tail of the screw center to accept a 1/4-in. drawbolt, which holds the tapered shaft tight from the back of the headstock through the spindle. The drawbolt is simply a length of threaded rod with a washer and wing nut. The second modification was to remove the screw center. This leaves a 1/4-20 threaded hole for attaching the work.

I cut the wheel blanks from scrap using a hole saw with a 1/4-in. pilot bit. Then I mount a blank on the modified center with an ordinary stove bolt. It takes about a minute to shape and sand each side. I try to completely finish one side before I turn the wheel around. While shaping, make sure the hub area is slightly thicker than the wheel rim for clearance.

For axles on the toys, I use 1/4-in. stove bolts screwed into a hidden nut mortised and epoxied in the vehicle’s side. This is stronger and longer-lasting than wooden axles and allows the owner to take apart the toy and put it back together.

George Pilling, Springville, Calif.

Fine Woodworking Magazine, October 1981 No. 30

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Log in or create an account to post a comment.

Sign up Log in