Modifying a Grinder to Sharpen Carving Gouges

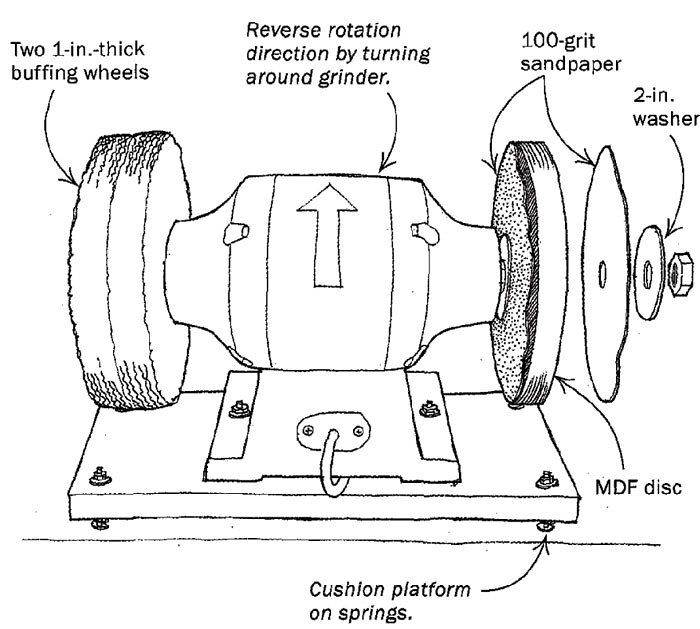

To sharpen wood carving chisels and gouges, start with a common grinder motor and turn around the grinder so that the wheels rotate away from you at the top, which will give you much more control. Mount the grinder on a platform supported by four springs to remove all vibration. Mount a plywood sharpening wheel (described below) on the right side of the grinder and sandwich two l-in.-thick cloth buffing discs on the left side to make an oversized buffing wheel.

To make the sharpening wheel, laminate plywood to produce a 6-in.-dia., l-in.-thick disc. If you don’t have a lathe, simply saw the disc to rough shape on a bandsaw, mount it on the grinder and turn it to final shape in place. Mount a disc of fine sandpaper (150 or 180 grit) to each side of the disc and a ribbon of sandpaper to the rim. Don’t glue the side pieces to the wheel: They should be allowed to float on a film of air as the wheel rotates. This allows you to apply a very gentle pressure with the gouge, thereby removing the risk of overheating the blade being sharpened. After sharpening the tool on the wheel, move to the cloth buffing wheel to polish and hone the edge.

Alex Cameron, Golden Grove, South Australia

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Olfa Knife

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in