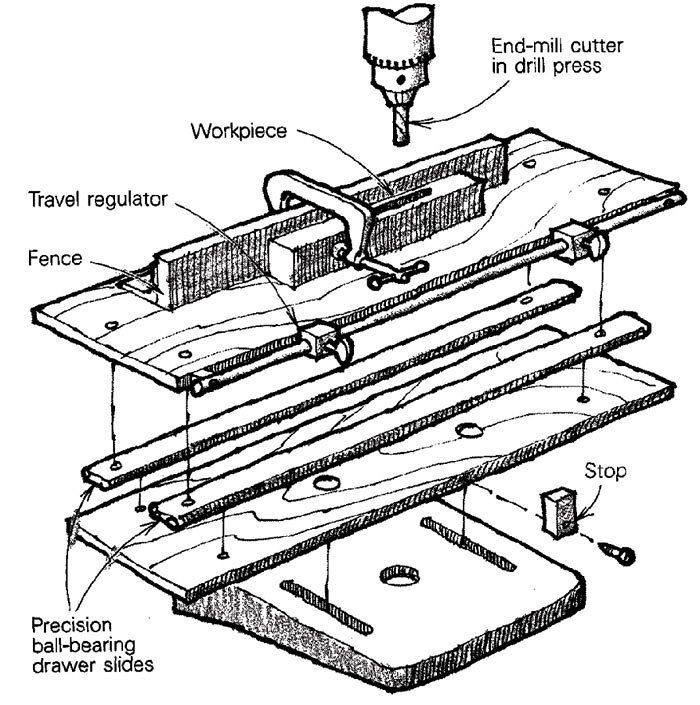

Mortising Table for Drill Press

Frustrated with hollow-chisel and router mortises, I made this drill-press mortising fixture, which works even better than I expected. Its secret is a pair of precision ball-bearing drawer slides. Precision drawer slides have less play than regular drawer slides, and move so smoothly that I’m sure there are other uses for them in the shop.

This is how the fixture works. First chuck an end-mill cutter in the drill press, then set the travel regulators to produce a mortise of the desired length. Now position the fence to center the mortise in the thickness of the stock. To cut the mortise to the desired depth, gradually lower the cutter while sliding the table back and forth.

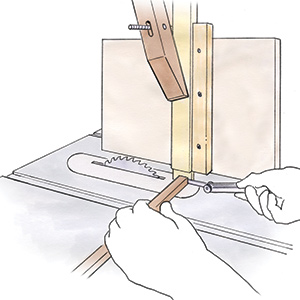

Rather than squaring up the ends of the mortise, I simply round over the tenon with a file.

David Grimm, Richmond, Mich.

Fine Woodworking Magazine, December 1983 No. 43

Fine Woodworking Recommended Products

Hedgehog featherboards

MicroJig Matchfit dovetail clamps

Leigh D4R Pro

Log in or create an account to post a comment.

Sign up Log in