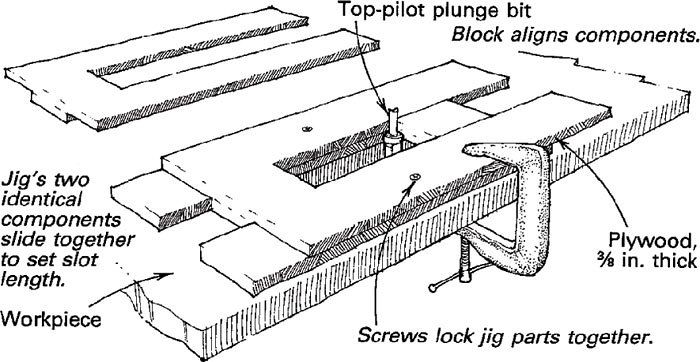

Plunge Router Slotting Jig

I build cabinets for audio, video and computer equipment. Each cabinet must be equipped with different-size access slots, depending on the equipment to be stored. To cut the various lengths of slots required, I came up with the router jig in the sketch. The jig, which I’ve found saves time and gives good results, is based on the two interlocking, identical parts cut from 3/8-in.-thick plywood. A block glued to each U-shaped component aligns the pieces as they slide together. For best results, the pieces must fit together snugly.

To use the jig, slide the halves to the desired slot length, secure the assembly with two screws and clamp it down in the desired location. I use a plunge router with an Amana top-pilot (on the shaft) flush-trimming plunge bit, which has several advantages over a standard router fitted with guide collars or bushings. First, with a plunge router, you can rout the slot incrementally without having to stop and reset the cutting depth, and second, with a flush-trimming bit, you don’t have to widen the jig slot to compensate for the collars. I have made several jigs for various slot widths, but the 1-1/4-in. width gets the most use.

Warren W. Bender, Jr., Medford, N.Y.

Fine Woodworking Magazine, February 1992 No. 92

Fine Woodworking Recommended Products

Incra Miter 1000HD

Double Sided Tape

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in