Production Setup for the Chopsaw

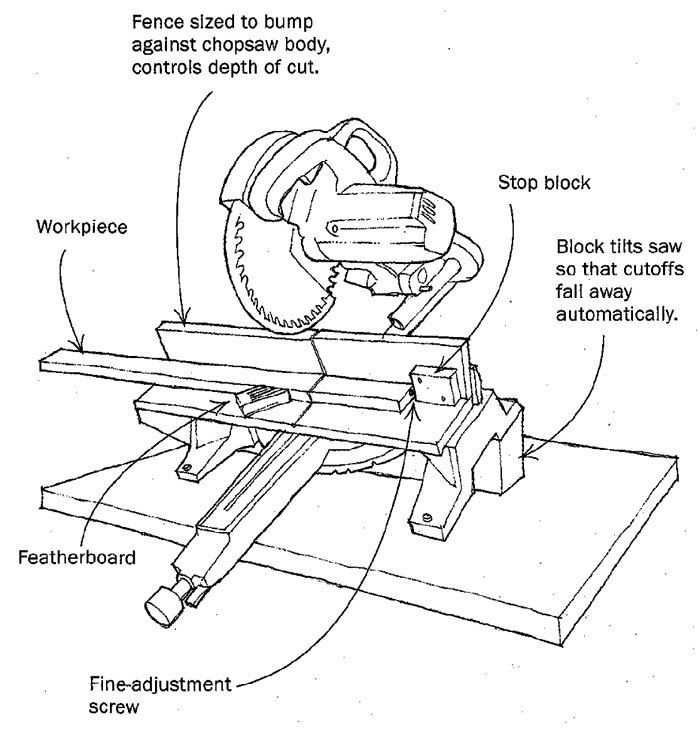

When cutting hundreds of identical pieces of wood to length for production work, a chopsaw is essential but not sufficient. To speed up cutting time, you need automatic removal of the sawn pieces. The easiest way to achieve this is to tilt the saw forward by attaching a 5-in. spacer board underneath the rear of the saw.

A simple jig is then clamped to the saw table to give you accurate results. The floor of the jig should be melamine or vinyl-coated to allow the pieces to slide off the jig easily. Secure the jig firmly to the saw. To help avoid tearout, screw a fence to the back edge of the jig. Cut the fence to the proper height so that it bumps against the saw body and acts as a depth stop, too.

On the fence, at the distance of the cut plus 1/2 in., screw a stop block equipped with a flat-head screw for fine adjustment and sawdust clearance. Finally, you need to screw a featherboard to the floor of the jig to keep the workpiece against the fence.

This jig is so easy to build that you can have one for each length you need to cut. You will save the time you spent building the jig the first time you use it.

Klas Wilzen, Glimmingeg, Malmo, Sweden

Fine Woodworking Magazine, April 1999 No. 135

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Double Sided Tape

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in