Raised Panels on the Jointer

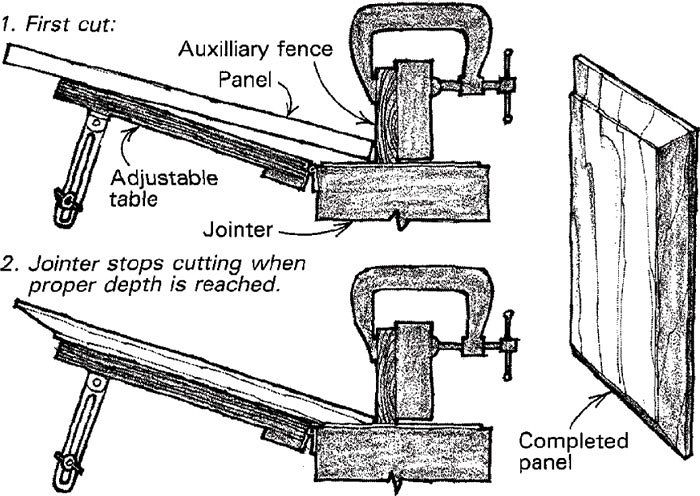

You can produce panels with beautiful long-tapered bevels on your jointer, provided it has rabbeting capability. Build an outboard table from 3/4-in. plywood about 12 in. wide and as long as your jointer. Mount the table to your jointer or jointer stand so that the outside edge may be raised or lowered to produce the desired angle. The inboard edge of the table should be about 1/4 in. from the jointer’s cutterhead.

Clamp a strip of wood to the jointer’s fence flush with the jointer’s bed to prevent the thin edge of the panel from sliding under. Three interrelated factors determine the shape of the bevel. The depth of the shoulder on the panel is determined by the height at which you set the infeed table. The distance from the fence to the end of the cutterhead determines the width of the bevel. The thickness of the edge of the panel is determined by the angle of the outboard table, the width of the bevel and the depth of the shoulder.

When the setup is right, turn on the jointer and slide the panel over the cutterhead. Since the shoulder will ride on the jointer’s infeed table when the proper depth is reached, you simply continue making passes until the jointer’s knives stop cutting. Cut the two end-grain sides of the panel first so that tearout will be removed when the other two sides are cut.

Norris S. White, Sellersville, Pa.

Fine Woodworking Magazine, June 1986 No. 58

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Starrett 12-in. combination square

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in