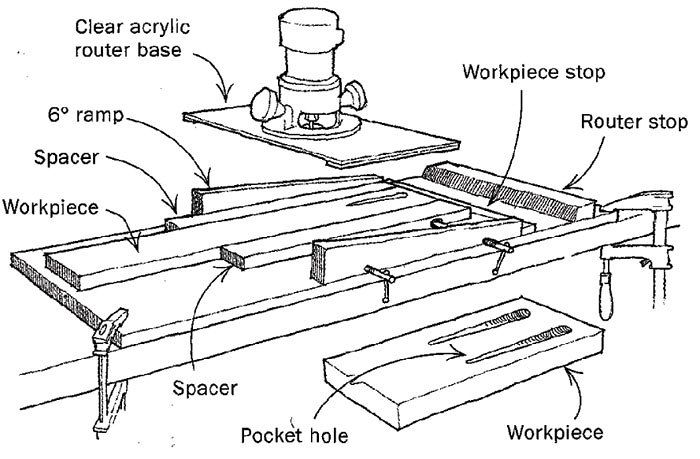

Router Ramp for Pocket Holes

I built this router-based pocket-hole ramp when I became frustrated with my drill fixture. The router slides down the ramps to cut a low, 6¡-angle pocket hole. It’s quick and simple. There’s no shifting of the workpiece and no frayed edges on the cut.

To make the fixture, attach two 6¡ ramps on each side of a plywood base. Install T-nuts and bolts in one of the ramps to provide a clamping system for the workpiece. Attach stops for the workpiece and the router at the base of the ramp. The distance between the router stop and the workpiece stop will determine the depth of the pocket hole, so position the stops carefully. Also, you will need to make an acrylic or Plexiglas base for your router. Add 1/4-in.- thick guide rails to the underside of the base to ride on the outside of the ramps.

To set up for a cut, place the workpiece in the fixture against the stop, positioning the workpiece so that the pocket cut will be in the right location. Drop in some scrap spacers to hold the workpiece in position. Tighten the clamps. Chuck a 3/8-in. round-nose bit into the router. With the router in place at the top of the ramps, turn it on, and slide it down to the router stop to make the pocket hole. Drill the pilot hole in the pocket after the workpieces have been clamped together. Use a 6-in. pilot bit and driver to keep the screw angle low.

Michael Csontos, Prescott, Ariz.

Fine Woodworking Magazine, February 1999 No. 134

Fine Woodworking Recommended Products

Leigh Super 18 Jig

Double Sided Tape

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Log in or create an account to post a comment.

Sign up Log in