Routing Dovetails on Turned Posts

When I finally decided to make Christian Becksvoort’s round Shaker stand (Fine Woodworking #110, pp. 70-73), I used a different technique for cutting the sliding dovetails into the base of the post. The usual approach is to index the post between centers on the lathe and build a box above the lathe ways that allows a sliding router to cut the dovetails. Being a one-armed woodworker, I didn’t feel comfortable with this approach.

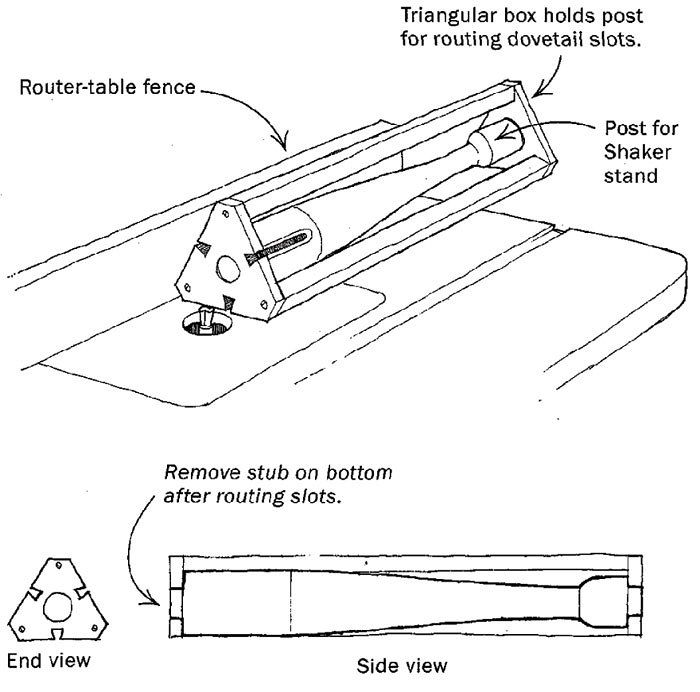

Instead, I made a fixture that is basically a triangular box. The post is locked into the box by stub tenons turned on both ends of the post that fit tightly into holes in the triangular ends of the fixture. I cut the dovetails by sliding the fixture along the router-table fence, then I remove the stub tenon on the bottom of the post.

To cut the slots, I used three router bits: A 3/4-in. straight bit to mill a flat (the base of the turned post protrudes slightly from the triangular box before you make this cut), a 1/2-in. straight bit to hog out the bulk of the waste and, finally, a dovetail bit to rout the dovetail slot. It is essential to use a stop block to control the length of the router-bit cuts. This jig is less trouble than a lathe jig and just as accurate and convenient, even for woodworkers who have two arms.

Leslie Davis, Tottenham, Ont., Canada

Fine Woodworking Magazine, October 2000 No. 144

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Suizan Japanese Pull Saw

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in