Routing the Edges of Odd-Shaped Pieces

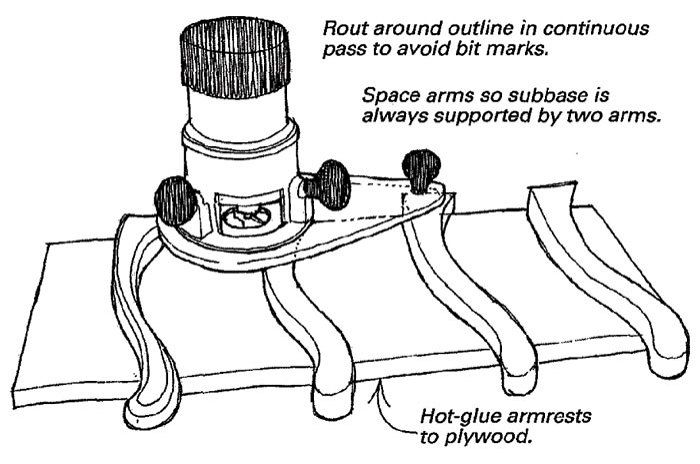

Shaping edges on small pieces with a router is always ticklish. I was recently faced with this problem when I needed to round over edges on some one-half scale tapered walnut rocking-chair arms. My magic mat wasn’t stable enough. And because I wanted to round over the perimeter in one pass to keep the cut smooth, I didn’t want to clamp and reclamp each arm. Also, I needed to prevent the router from rocking on the small surface.

I solved the problem by hot-gluing all four armrests to a scrap piece of birch plywood, spaced 8 in. apart, in line and parallel. I used the extended subbase on my router supported by the adjacent armrest to steady the router. After shaping one side, I pried the armrests off and flipped them over to rout the other side.

It took only two little dabs of hot glue on each armrest to hold them. The dried glue, and occasional flakes of plywood veneer, were easily removed with a scraper. I’ve since used this technique successfully on other small parts where I needed a stable base and didn’t want to spend a lot of time clamping and reclamping each piece.

Dave Coumes, Franklin, Tenn.

Fine Woodworking Magazine, December 1994 No. 109

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Incra Miter 1000HD

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in