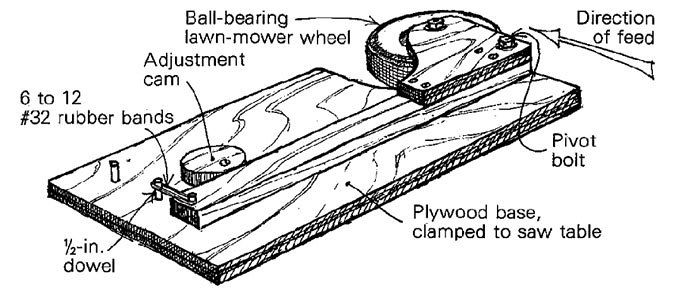

Rubber Tire Hold-In

The simple lawnmower-wheel fixture sketched above has made featherboard hold-ins obsolete in my shop. I have two: one as shown and the other a mirror image of the first. I use them on both the table saw and the router table for ripping, cutting grooves, shaping, and other operations.

The advantages of this fixture over featherboards are significant: Feed friction is greatly reduced, hold-down pressure is adjustable and consistent (even when the stock is uneven), and setup is quicker and easier. Since fore/aft friction is all but eliminated, there is little tendency for the fixture to squirm and turn under the clamp. Only one clamp will keep it in place, even on a waxed saw table. The disadvantage is that there is no kickback resistance as with featherboards. But kickback can be all but eliminated by using sharp, clean blades, and carefully setting up for each cut.

The idea for rubber-tire pressure wheels is not mine similar fixtures are used on large power-feed industrial woodworking machines. I suppose the wheel could be cut from plywood to save the extra few dollars for the ball-bearing lawnmower wheel and special axle bolt. But I find it comforting to see the rubber tire flatten a bit as it pushes the work against the saw fence.

Bob DeFrances, Delray Beach, Fla.

Fine Woodworking Magazine, February 1981 No. 26

Fine Woodworking Recommended Products

Hedgehog featherboards

Stanley Powerlock 16-ft. tape measure

Blackwing Pencils

Log in or create an account to post a comment.

Sign up Log in