Shaping Curved-Top Panels

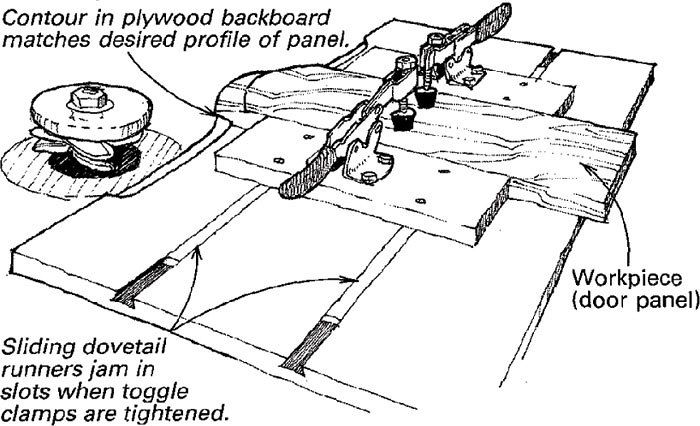

When shaping curved-top panels for cathedral-top cabinet doors, I use the standard approach a plywood jig with a curved contour cut into its top, which guides along a ball bearing rub collar mounted below the shaper cutter. But for the jig to work properly, you have to eliminate any side-to-side movement in the workpiece as it’s being shaped. My original solution to the problem was to use fixed blocks attached to the plywood jig on either side of the workpiece with De-Sta-Co toggle clamps mounted on the blocks. I would cut filler strips to wedge between the blocks and the workpiece to center the work and to keep it tight. As the panel widths changed from door to door, I would cut new filler strips. Any panel that went beyond the capacity of the toggle clamps meant that I had to unscrew the blocks and reposition.

Finally, I redesigned the jig by mounting the plywood blocks to sliding dovetail runners. After centering the workpiece, I slide the blocks into position on either side of the workpiece and toggle the clamps down. The clamping pressure lifts the sliding dovetails, which wedges them into the slots and clamps the whole thing tightly. Then I’m ready to shape.

The combination of sliding dovetails and toggle clamps has promise for holding down materials in other applications, too.

Tom Griffin, Dublin, Calif.

Fine Woodworking Magazine, December 1993 No. 103

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Log in or create an account to post a comment.

Sign up Log in