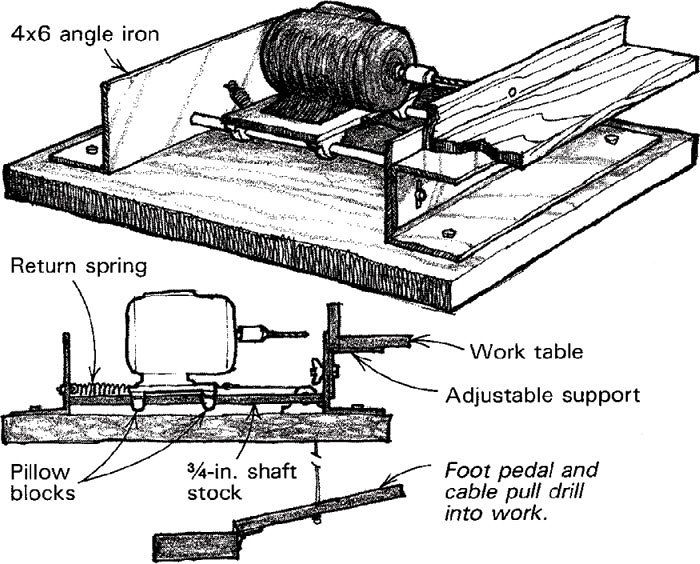

Shop-Built Doweling Machine

In my one-man cabinet shop I used a doweling jig to drill holes for dowel joints in cabinet door frames and the like. Although I found this procedure too slow, when I went shopping for horizontal boring machines I found them too expensive. Basing my design on a few sketches I made on my shopping trip, I built the machine shown above for about $260, which included $120 of machine shop expense.

The machine consists of two opposed 4×6 steel angle iron sections bridged by two 3/4-in.-dia. steel shaft-stock rails. Boring is accomplished by a 1/2-HP, 1725-RPM motor that slides down the rails on pillow blocks. The sliding action is provided by a low-tech (but effective) pulley, cable and foot-pedal arrangement. A strong coil spring attached to the back of the motor base pulls the motor back out of the hole when the foot-pedal is released. The work table is adjustable vertically, as shown in the sketch, to accommodate different stock thicknesses.

Since the rails must be perfectly parallel I had a machine shop drill the critical rail holes in the angle iron pieces. The machine shop also threaded the rail ends and reworked the motor shaft to accept a chuck.

Hjardar Bruun, Ferndale, Wash.

Fine Woodworking Magazine, February 1986 No. 56

Fine Woodworking Recommended Products

Hedgehog featherboards

Incra Miter 1000HD

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in