Shopmade Sliding Crosscut Table

Most woodworkers appreciate the performance and accuracy that a sliding table would lend to their tablesaw, especially one with enough capacity to crosscut a full sheet of plywood. But for most of us, the costs in dollars and valuable floor space make such a piece of equipment prohibitive. Addressing those concerns, I decided to make my own sliding table based on the principle of a heavy-duty full-extension drawer slide. For everyday use, the extension table is locked onto the base and doesn’t take up any extra floor space in front of the saw. But when I release a small lever, I can pull back the extension table to make a 49-in. opening and crosscut a full sheet of plywood.

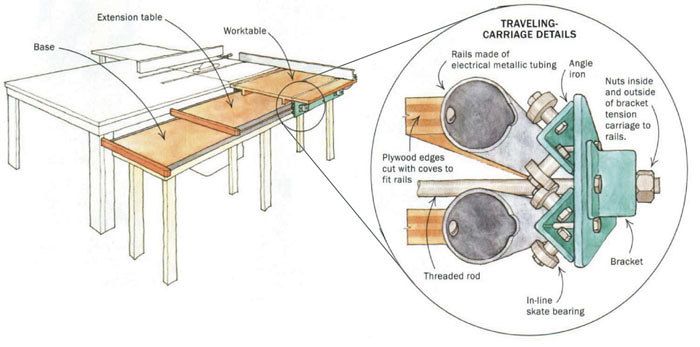

The table consists of four main parts: the base, the extension table, the traveling carriage and the worktable. Start by constructing the base and the extension table of 3/4-in. plywood. Rout a cove into the edges of these two pieces to accept lengths of electrical metallic tubing, which become the rails for the traveling carriage.

Make the traveling carriage from two pieces of 4-in. flat steel plate with two pieces of angle iron bolted along each top and bottom edge to hold the in-line skate bearings that provide the rolling action. These two steel-plate assemblies are held together and tensioned by means of two threaded rods that pass between the base and the extension table, and they’re locked in place by nuts inside and outside the metal brackets on each end of the carriage (click on the drawing to see a larger version). Screw the worktable to the extension table using two spacers so that the worktable clears the traveling carriage. I added aluminum T-slots in the top of my worktable so that I can angle the fence in relation to the blade.

Jack Hegarty, Tottinham, Ont., Canada

Fine Woodworking Magazine, February 2001 No. 147

Fine Woodworking Recommended Products

Double Sided Tape

Stanley Powerlock 16-ft. tape measure

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in