Shopmade Steady Rest

In the process of turning dozens of spindles for a bed I was making, I found I needed a steady rest to stabilize the thin spindles during the later stages of turning. I came up with a design that is easy to build, easy to adjust and works admirably.

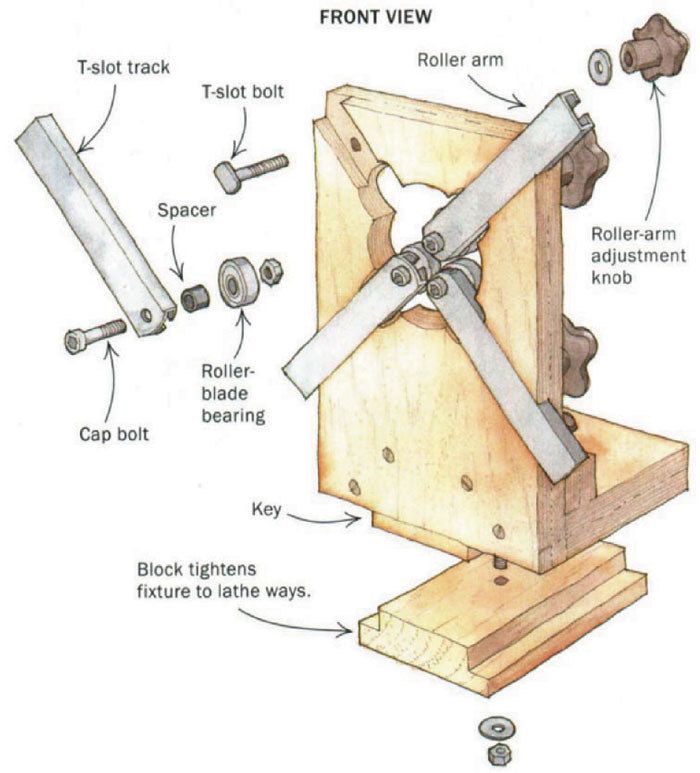

The steady rest consists of a main body and four roller arms. For the body, I laminated two pieces of 1/2-in.-thick Baltic-birch plywood. I made the roller arms by mounting roller-blade bearings (available from large sporting-goods stores) to the ends of 6-in. lengths of T-slot track. The roller arms adjust and lock into position with T-slot bolts and plastic knobs. T-slot hardware is available from Woodcraft (800-225-1153) and other mail-order suppliers.

To make the steady rest, start by cutting out the vertical part of the body from the Baltic-birch plywood and locating the lathe’s centerline on it. You can find and mark the centerline’s height above the lathe bed by placing the vertical piece on the lathe bed and squeezing it between pointed centers. Cut two dadoes into the vertical part of the body (for the T-slot tracks) in an X pattern, with the X centered over the centerline point. Cut a circular opening through the body that is big enough for the largest spindle you will be turning, then drill holes for the hardware as necessary. Add a key to the bottom of the body to keep it centered and straight on the bed of the lathe. You will need to tailor the key and the fixture’s bed-locking mechanism to your lathe.

To use the steady rest, slide it onto the spindle, lock the fixture to the bed, then adjust the roller arms so that the bearings ride gently against the spindle and support it during turning.

Robert D. Eberhardt, Eau Claire, Wis.

Fine Woodworking Magazine, August 2000 No. 143

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Incra Miter 1000HD

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in