Sphere-Turning Lathe Attachment

In 1946, a friend described a ball-turning device his machinist had made to fit an Atlas lathe. Unfortunately, I never got a chance to look at it. I’ve tried to design and make an attachment ever since, and recently I succeeded. Although the machinist had made the fixture entirely of metal, I used wood for the fixture’s core and reinforced it on the sides with sheet brass.

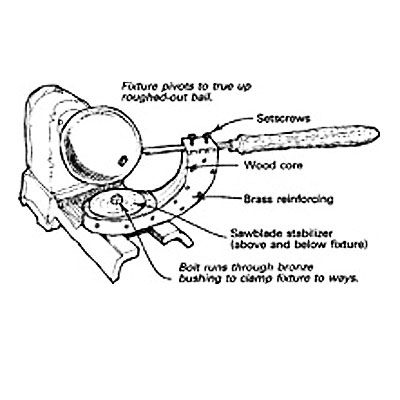

The fixture bolts to the lathe’s bed and holds a gouge at a height that’s on line with the lathe’s centers. Then, with the lathe running, the fixture is pivoted to make the final cleanup passes on a previously roughed-out ball. The final diameter of the sphere is determined by the projection of the gouge’s tip from the block.

To make the fixture, I bandsawed the wooden core from an old bridge beam and machined the top and bottom of the base flat with a rotary planer in a drill press. Then, I drilled a 5/8-in.-dia. hole through the base to take a bronze bushing. The bushing’s length is critical; it must extend from the tool-rest attachment bracket below the ways that I use for bolting the fixture to the lathe bed, up through the base of the fixture and 1/64 in. above the upper steel plate. If the bushing is shorter, the fixture will be clamped tightly to the lathe and won’t rotate; any longer and there will be too much slop as the fixture pivots. The steel plates are actually sawblade stabilizers from Sears (part no. 94952). They have a 5/8-in. hole, just right for the bushing, and act as large washers that the fixture’s arm pivots between. Following a cardboard pattern, I cut out the 3/32-in.-thick hard sheet brass that surrounds the wood core, and drilled and countersunk it for screws. I used 1/8-in.-thick brass for the cap, which I dovetailed into the brass sides and tapped for the setscrews that hold the gouge.

The gouge sits in a groove cut into the top of the core under the brass cap. It’s critical that the gouge’s cutting edge be the same height as the lathe’s center; so adjust the depth of the groove for the gouge you’re using.

Ralph M. Luman, Virginia Beach, Va.

Fine Woodworking Magazine, August 1990 No. 83

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

MicroJig Matchfit dovetail clamps

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in