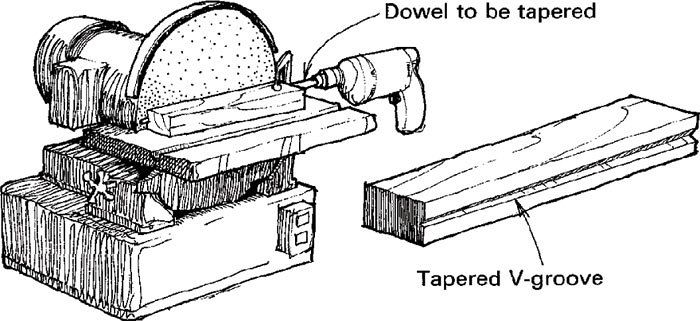

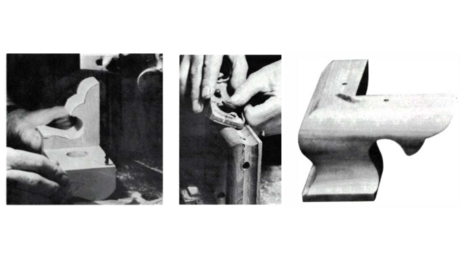

Spindle Tapering Jig

Recently I needed a quantity of tapered wood rods to make drop spindles for spinning wool. The spindles’ diameter had to taper from 1/2 in. to 1/4 in. evenly along their 12-in. length. Rather than attempt to turn these tiny spindles on the lathe, I designed the jig shown above, which worked perfectly.

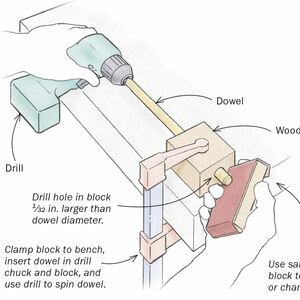

First I selected a 12-in.-long chunk of 1-1/2-in.-thick hardwood for the sanding guide and sawed a 1/2-in.-deep V-groove into one edge. After cutting the groove, I ripped the guide at a slight taper so the groove was only 1/4 in. deep at one end. To use the guide, I clamped it to the worktable of a disc sander, with the grooved edge almost flush against the disc. Then I chucked a length of dowel in an electric drill, and with the drill at slow speed, guided the dowel into the V-groove. After a little practice and some trial-and-error setting of the guide, I was able to make perfect tapers every time.

Bert G. Whitchurch, Hemet, Calif.

Fine Woodworking Magazine, February 1989 No. 74

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in