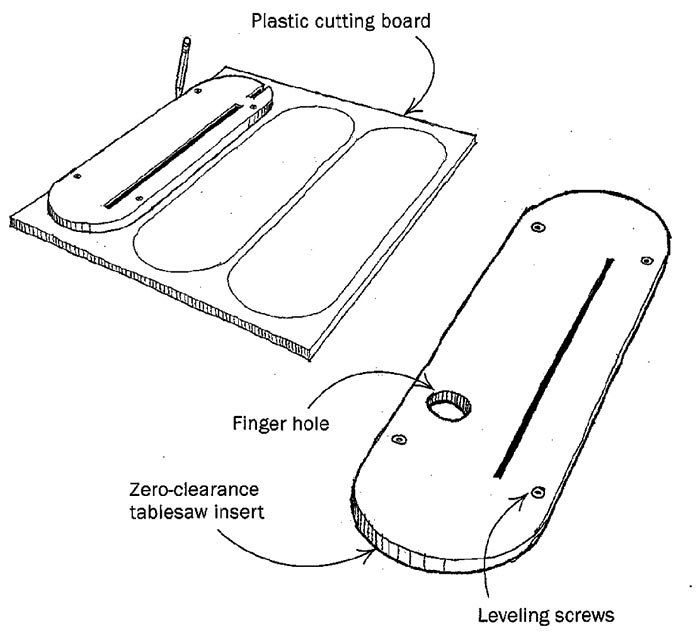

Table Saw Insert From a Kitchen Cutting Board

When I discovered the cost of aftermarket zero-clearance throat inserts for my tablesaw, I decided to make my own. I bought an ordinary white, high-density plastic kitchen cutting board, 1/2 in. thick. I marked and cut out several inserts, using the existing metal one as a template. I then drilled and tapped four holes in each insert to install leveling set screws. I also drilled a finger hole to make it easy to remove the insert from the saw table. The cuttingboard material is ideal because it is inexpensive, friction-free, dense and stable. I was able to make several inserts for less than the price of one commercially available piece.

Scott Spierling, Sunnyvale, Calif.

Fine Woodworking Magazine, October 1999 No. 138

Fine Woodworking Recommended Products

Double Sided Tape

Dividers

Bessey EKH Trigger Clamps

Comments

Why oh why didn't I ever think of this? I've been using melamine on fiber board, which works, but is a little flaky.

I'm off to the hardware store to buy some cutting boards!

Log in or create an account to post a comment.

Sign up Log in