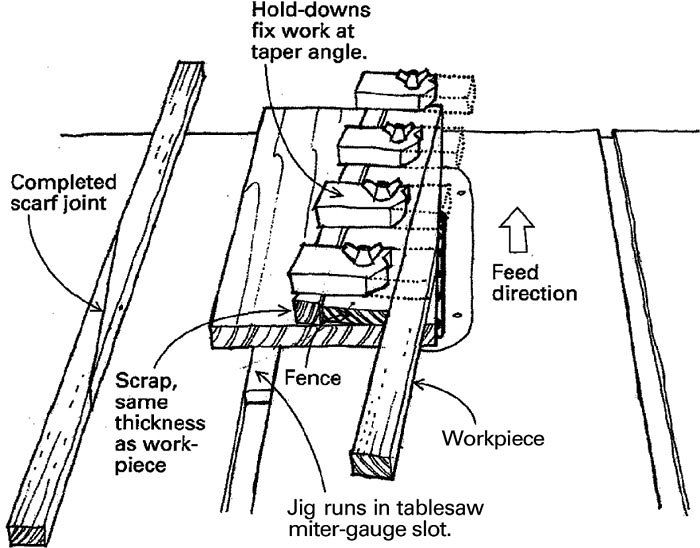

Table Saw Jig for Making Scarf Joints

The scarf joint, which joins stock lengthwise without loss of strength, deserves more recognition outside its traditional domain of wooden boatbuilding. Here’s how I make the joint for other woodworking projects.

Make a tablesaw jig from a scrap of 1/2-in. plywood, about 8 in. wide by 32 in. long. Attach a runner to the bottom of the jig to ride in the miter-gauge slot. Trim the edge of the jig with a pass through the sawblade. Now attach a 5/8-in.-high fence angled to the blade at 5¡ (a slope of 12:1). Install four or five hold-downs with machine bolts and wing nuts, as shown.

To use the jig, locate the piece to be scarfed tightly against the fence, and clamp with the hold-downs. Support the left side of the hold-downs with a piece of material the same thickness as the workpiece. With the sawblade set slightly deeper than the material to be cut, make a pass through the saw.

To keep the joint parts in registration during glue-up, drill a small hole through the splice, and drive in a small round dowel or bamboo skewer.

William R. Fuller, Dewitt, N.Y.

Fine Woodworking Magazine, February 1996 No. 116

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Festool DF 500 Q-Set Domino Joiner

3M Blue Tape

Log in or create an account to post a comment.

Sign up Log in