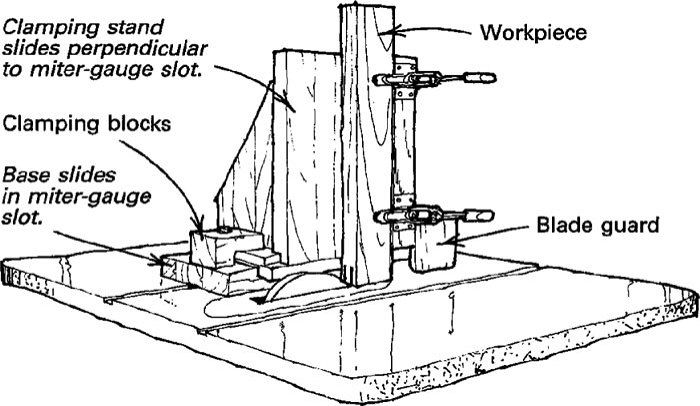

Table Saw Tenoning Fixture

A good tablesaw tenoning fixture must be heavy, strong, rigid and accurate. That’s why I made my massive tenoning fixture from an old laminated-maple, science-lab tabletop. The fixture has two main parts: a base that slides in the miter-gauge slot on a steel key and a vertical clamping stand that slides across the base perpendicular to the miter-gauge slot. Clamping blocks are bolted into the base to hold the vertical stand in place after it’s been moved into position to cut the correct-size tenon. Permanently attached lever-action clamps, like those by De-Sta-Co., screwed to the fence on the vertical stand hold the workpiece. As a safety feature, I added a blade guard on the trailing end of the fixture.

On production runs, I cut the tenon in one pass by mounting two identical blades separated by spacers, which set the final thickness of the tenon. Normally, though, when I have just one or two tenons to cut, I use a single blade and flip the workpiece for the second cut.

Joe Moore, Brockville, Ont., Canada

Fine Woodworking Magazine, June 1990 No. 82

Fine Woodworking Recommended Products

Double Sided Tape

Woodriver Circle Cutting Jig

Olfa Knife

Log in or create an account to post a comment.

Sign up Log in