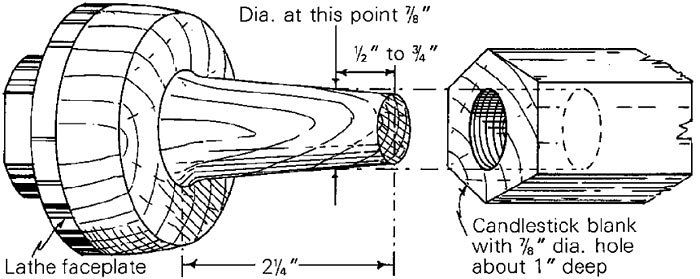

Tapered Turning Head

When lathe-turning candlesticks or other items that have a center hole, the hole can be perfectly centered by drilling it first before turning is started, and then using a tapered turning head, such as the one shown. If the candlesticks are to be for standard 7/8-in. diameter candles, taper from a large diameter of about 1-1/8 in. down to a minor diameter of about 13/16 in. or slightly less. The important dimensions are 7/8-in. diameter at 1/2 in. to 3/4 in. from the small end, along with a smooth, straight taper.

The predrilled wood blank is slipped over the tapered head. Care must be taken not to overtighten, of course, as the taper will split the wood blank if too much force is applied. Making the overall length of the taper about 2-1/4 in. and using the diameters indicated seem to provide good tightness and good tool clearance for standard candlesticks.

Cutting away stock from the top of the turning adjacent to the tapered head shortens the workpiece and consequently loosens the grip of the head, so if you must cut at that point, be sure to remove only a small amount before stopping the lathe and retightening the tailstock. When finished, the work can be removed easily by backing off the tailstock and moving the work slightly from side to side until loosened. The result is a perfectly centered hole. This method has one other advantage: You proceed with turning after you know that you’ve drilled a good clean hole.

The same concept can be applied for other center-hole pieces as well by turning other tapers with different diameters. If you have several tapers, it’s best to mount each one permanently on its own faceplate to ensure concentricity.

L.L. Chapman, Newark, Ohio

Fine Woodworking Magazine, Fall 1978 No. 12

Fine Woodworking Recommended Products

Incra Miter 1000HD

Milescraft 4007 6in Bench Clamp

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in