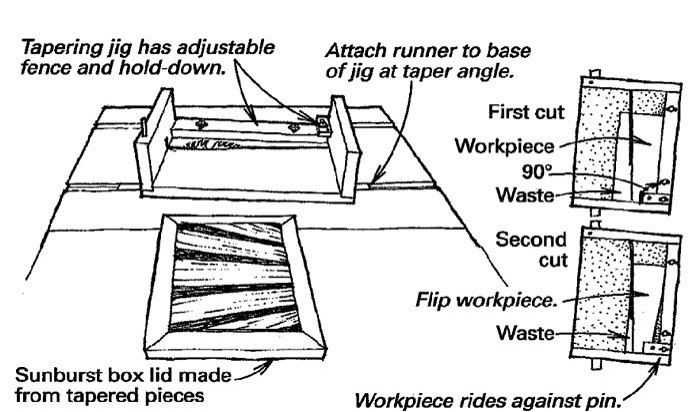

Tapering Jig Can Handle Small Pieces

My jewelry boxes feature a sunburst pattern on the lid, which I make by gluing up nine or so tapered pieces into a fan shape. The jig that I use to cut these small tapered workpieces on my tablesaw is built like a miniature sliding crosscut table. One big difference, however, is that the runner (which fits in the tablesaw’s miter-gauge slot) is attached at an angle to the centerline of the jig. The runner angle should be half the desired taper angle, which for my jig is 4¡. An adjustable fence to the right of the kerf determines the width of the tapered piece’s wider end. The lower end of this fence has an adjustable hold-down that registers the workpiece for the second pass. With this jig, you can vary the width of the workpiece but not the taper angle.

Equally taper both edges of the work. Here’s how I do it: I draw each tapered piece to scale, and then I measure the dimensions. Next I set the jig’s fence to the width of the workpiece’s wider end (the end that meets the sawblade first), and I make the first taper cut. I place a brass pin (stored in the jig’s rear cross brace when not in use) in the hold-down and adjust the pin to the width of the trapezoid’s narrower end I flip the blank over and make the second cut.

David M. Freedman, Cross Plains, Wis.

Fine Woodworking Magazine, February 1995 No. 110

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Veritas Wheel Marking Gauge

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in