Thickness Sanding on the Drill Press

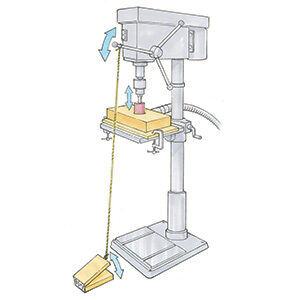

One day when my large thickness sander was down for repairs, I needed to make a length of very thin banding for an antique I was restoring. Within an hour, I had made the drill-press thickness-sanding fixture shown above from scraps around the shop. It works exceptionally well. With it, I can turn out a length of 1/32-in.-thick banding in a minute.

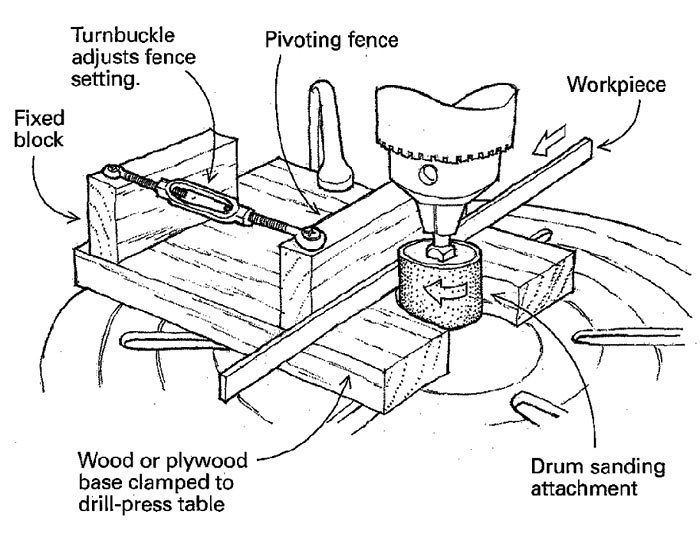

The fixture consists of a plywood base, cut on one edge to receive the sanding drum, and a pivoting fence that adjusts via a small turnbuckle. The other end of the turnbuckle is attached to a fixed block glued to the base. I brushed some shellac on the threads to prevent the turnbuckle from vibrating and turning during use.

To use the fixture, I cut a rough strip on the tablesaw and feed it against the rotation of the sanding drum with one hand while pulling with the other. The trick is to keep the strip flat against the fence and feed it steadily. I give the turnbuckle a half-turn on each pass until I sand the strip to the proper thickness. The device is safe to use and will sand down a strip of wood to a thickness almost like that of paper. I now use the fixture for making guitar binding and purfling.

E. Richard Goodall, Salmon Arm, B.C., Canada

Fine Woodworking Magazine, August 1997 No. 125

Fine Woodworking Recommended Products

Double Sided Tape

Milescraft 4007 6in Bench Clamp

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in