Three-Jaw Overshoes for Bowlturning

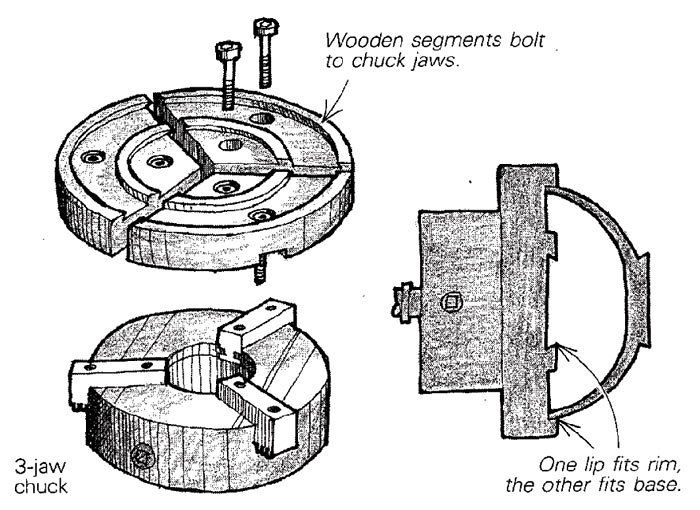

Like many avid woodturners, I use a three-jaw chuck for bowlturning and other faceplate work. With it you can avoid screw holes in the bottom of the bowl or skip the step of gluing on a waste bottom with paper between. But the three-jaw chuck is limited in the size range it can hold, and it contacts the workpiece at only three points, limiting the strength of its grip if you overtighten it you will mar the work. I overcome these problems by adding wooden “overshoes” to the chuck. The overshoes, shown above, are simply three 2-in. thick, wooden circle segments. I cut a groove in the back of each segment and bolt the piece to the jaw with two countersunk Allen bolts. Annealed chuck jaws, which can be drilled and tapped for the bolts, are available for most chucks; it’s handy to have more than one set.

In the face of the wooden overshoes I turn two recesses, slightly dovetailed, to fit the rim and the base of a bowl. I mark both the overshoe segments and their matching jaws if removed, each overshoe must go back on the same steel jaw it came off.

To use the overshoe chuck, I first mount the bowl blank on a large screw center and turn the outside to rough dimensions, taking care to size the base within a range that will fit the overshoe chuck. Then I reverse the blank, remount with the overshoe chuck gripping the base, and turn the inside of the bowl. When the inside is complete, I reverse the bowl in the chuck, gripping it by the rim to complete the outside. This technique is particularly useful when working green wood, which must be turned rough, dried, then remounted for turning to final shape and finishing.

A.R. Hundt, Blackmans Bay, Tasmania

Fine Woodworking Magazine, August 1983 No. 41

Fine Woodworking Recommended Products

Incra Miter 1000HD

Woodriver Circle Cutting Jig

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in