Tripod Jig

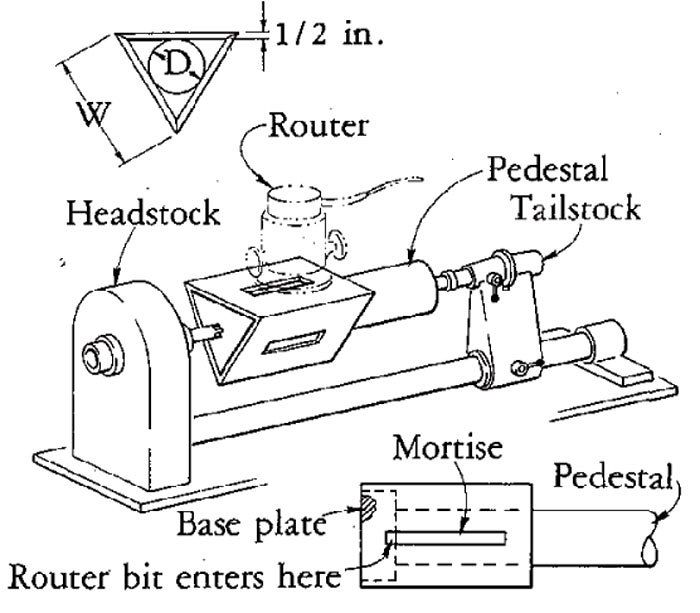

With the aid of this homemade jig, mortises for tripod table legs can be routed while the pedestal is on the lathe, after it is turned cylindrical and before it is turned to shape. The jig consists of a triangular box that fits around the cylinder, with mortises in its faces to guide a router bit. To build the jig, first make a full-scale drawing of the pedestal bottom and construct an equilateral triangle around it. Draw another triangle 1/2 in. outside the first one, as shown. Then cut three rectangular pieces of 1/2-in. plywood to the width determined by the drawing and about twice as long as the mortises will be. With table-saw blade set at 60¡ and plywood held vertically against the fence, cut the long edges at a 30¡ angle. Then cut mortise templates in the exact center of each piece a dado blade simplifies the operation; chisel the ends square. The width of the mortises will vary according to the router bit and template follower you plan to use. For the back piece of the jig, bandsaw an equilateral triangle of 1-3/4-in. thick scrap wood to fit. Then glue and nail the four pieces together.

With the pedestal cylinder held by the tailstock of the lathe, position the jig and center the headstock spur on its bottom plate. Triangular spacers may be inserted between the pedestal and jig base to adjust the length of the mortise. Rout the first mortise, turn jig and pedestal 120¡, mortise, and repeat.

To cut dovetail housings, first remove the bulk of the wood with a straight bit the diameter of the dovetail waists, then rout out the sloping sides with a dovetail bit.

Lyle Terrell, New Orleans, La.

Fine Woodworking Magazine, Winter 1977 No. 9

Fine Woodworking Recommended Products

Craftsman Random Orbit Sander

Fein Turbo II HEPA Wet/Dry Dust Extractor

Double Sided Tape

Log in or create an account to post a comment.

Sign up Log in