Wooden Bearings for Outboard Lathe

Several years ago, I needed an outboard faceplate lathe for turning large plates. While considering ways to home-build the lathe, I remembered that as a young fellow I had helped my wife’s dad as an oiler on a threshing machine. The contraption had a number of low-RPM shafts, which turned in hard-maple pillow blocks.

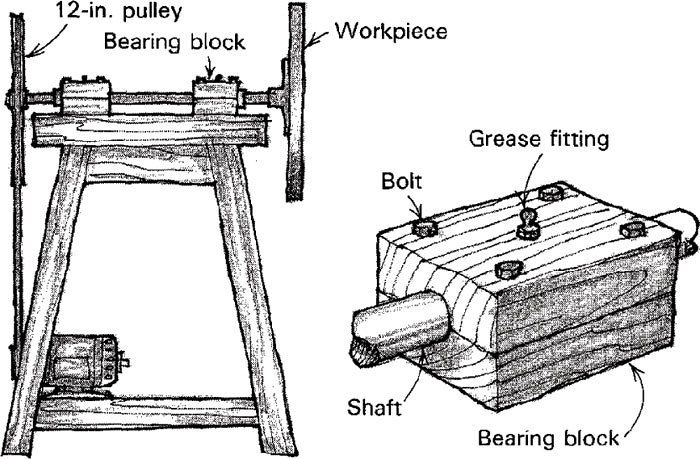

Adapting the idea to the project at hand, I purchased a 20-in. long, 1-in. thick shaft, fitted a 12-in. pulley (reclaimed from a clothes dryer) to one end, and threaded the other to accept standard faceplates. The shaft runs in two hard-maple pillow blocks, which are lubricated through grease fittings installed in the top.

The whole arrangement is bolted to a sturdy bench, and is run by a motor and belt from below.

Vic Johnson, Lincoln, Nebr.

Fine Woodworking Magazine, June 1985 No. 52

Fine Woodworking Recommended Products

Double Sided Tape

Incra Miter 1000HD

Milescraft 4007 6in Bench Clamp

Log in or create an account to post a comment.

Sign up Log in