All About Hand Tool Skills

In this golden age of electric-powered machinery, knowing the basics of handsaws, planes, chisels, and measuring and marking tools is an essential skill set that can add quality and personality to your work. However, using hand tools takes practice and patience, and there are a number of tips and techniques to help you through the learning process.

The Basics:

• The essential toolkit: Start with a few standard tools.

• A time and place: Know when to reach for a hand tool vs. a power tool.

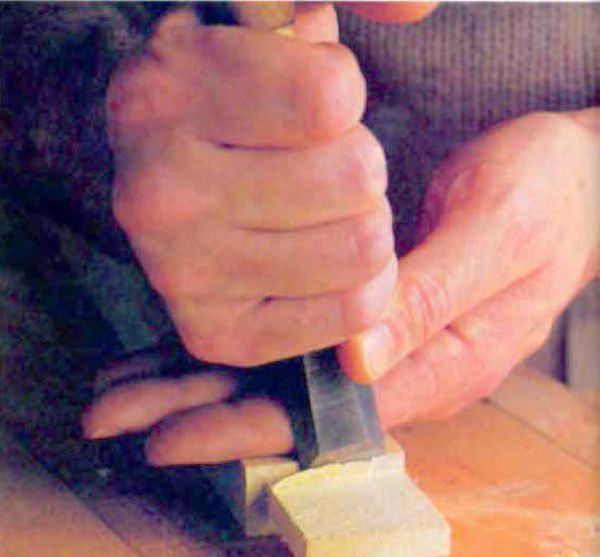

Using chisels

The chisel is a versatile tool that can be quickly remove big chunks of wood or delicately pare away thin shavings. Chisels are essential for cutting and fitting hand-cut joinery. They also come in handy for many other tasks in the shop, from removing excess glue to trimming pegs and pins. Chisels vary in type depending on the work you are doing. Some have long, thin blades (ideal for delicate paring), while others feature short, stout blades designed to hog out waste and survive a heavy mallet blow.

Using handplanes

For hundreds of years, woodworkers have used the handplane to prepare stock and furniture parts, and it still excels at preparing a finished surface. A handplane is essentially a reference edge (sole) that guides a blade (iron) across a surface or edge. The wide variety of plane types available illustrates the variety of surfaces and profiles that a plane will cut. For example, a shoulder plane will trim a fat tenon or cut a rabbet into the edge of a board; a compass plane will smooth a curved surface; and a bench plane can produce a flat surface on a 10-ft. piece of rough lumber. Knowing how to use a handplane also means knowing how to sharpen it and tune it up.

Using handsaws

Handsaws range in size from the cylinder-handled gent’s saw, up to the dovetail saw, the tenon saw, and the panel saw. In addition to size and handle variations, handsaws differ in how their teeth are set. Crosscut saws feature an alternating tooth pattern that scores the wood as it cuts, while ripsaws have all their teeth in a line. The Japanese saw, used for similar tasks as the aforementioned Western-style saws, cuts on the pull stroke rather than the push stroke. Cutting straight and with control is a skill that comes with practice; unless you’ve mastered the technique, practice on scrap wood before you cut into the real thing.

Marking and layout

Hand-cut joinery relies on proper measuring and marking tools. Guiding a saw by hand, for instance, requires that you first scribe a line to follow. In addition to guiding you through a procedure, scribe lines can reduce potential tearout by cutting the wood fibers at the surface and preventing a blade from wandering off course. This and other marking tasks can be accomplished with a basic set of measuring and marking tools: a tape measure or rule, a square, a marking gauge, and a marking knife. There are scores of other tools to choose from as you expand your repertoire of techniques.

The right time for hand tools

Many of the tasks traditionally accomplished exclusively with hand tools can be completed much more efficiently and quickly with power tools. The router alone has shaved hours off tedious edging and trimming operations. However, hand-tool skills can be a great complement to modern technology. Sometimes there is no faster option than using a backsaw to trim a tenon or a chisel to remove a clogged mortise. Other times, using a hand tool to complete an operation is just more enjoyable than setting up power tools.

Fine Woodworking Recommended Products

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Stanley Powerlock 16-ft. tape measure

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in