All About Shaping Wood

Shaping wood is intrinsic to woodworking. Unless you are making tree-shaped objects, a series of cuts is always required. Beyond the basic square, there are a variety of tools and techniques for shaping furniture parts.

The Basics:

• Hand-shaped parts: Files, rasps, and planes are for shaping everything non-square.

• Shaped with power tools: Templates, jigs, and fixtures are essential.

Hand-shaped parts

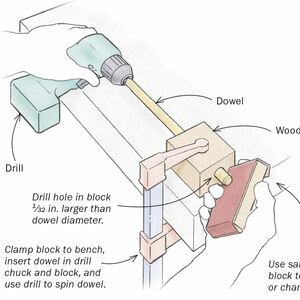

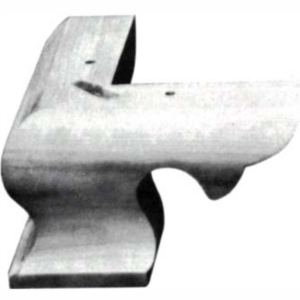

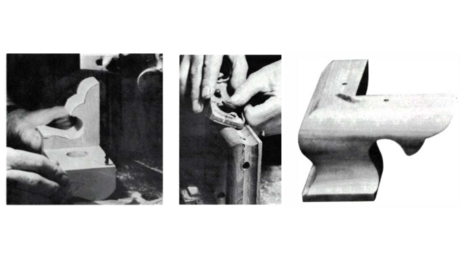

When shaping furniture parts, power tools can take you only so far. Most of the time, hand tools are required to finish the job, whether it’s scooping out a chair seat with planes, an adze, or scorp, or softening an edge with files and rasps. A cabriole leg requires hand tools to blend the transition from the turned leg to the pad foot, and a ladder-back chair requires using a drawknife to shape the spindles. For most of these tasks, power tools can’t do the job with the quality and character that hand tools can impart.

Shaped with power tools

Sam Maloof is famous for his unorthodox methods of shaping chair parts freehand on the bandsaw. That’s probably the most extreme example of using a power tool to shape wood and furniture parts, but there are many more common techniques available to woodworkers. The tablesaw can cut large-radius cove molding by setting up a fence that guides stock diagonally across the tablesaw blade. And a router can cut any conceivable shape with templates made of plywood, MDF, or Masonite.

Without jigs and fixtures, many power-tool shaping operations would be unsafe. Shopmade clamping aids can hold a workpiece in an unlikely position. Other power-tool jigs can guide a blade or bit along a delicate edge.

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in