Heating Your Shop

For every shop and climate, there's an efficient solution

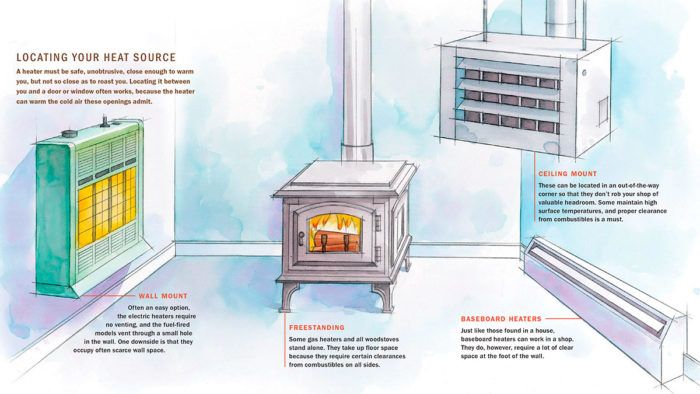

Synopsis: Whether your shop is located in an attached garage, basement, or outbuilding, keeping it warm during the winter months is important for woodworkers in most regions. Don’t go shopping for a shop heating system without first reading this overview by Fine Woodworking senior editor Andy Engel. From choosing the type of heater and learning about the different ways heat warms a building to comparing fuels and deciding where to locate a heater safely in your shop, this article covers it all.

My first woodworking shop was in a garage in northern New Jersey. I cobbled together some insulation, weatherstripping, and an old woodstove to make the shop mostly habitable—for me. For my tools and projects, though, I suspect it was a hostile environment. Morning often found the shop below freezing, which precluded storing glue or waterborne finishes there. Stoking the stove quickly launched the mercury into the 80s, a fluctuation in temperature and humidity that did my lumber no good. And, if the shop remained unused for any length of time during the winter, rust bloomed on my tools.

|

Better insulation and a heater I was comfortable burning in my absence would have fixed the problems. I think 50°F is good for an empty shop, and with decent insulation and air sealing, it’s a temperature that shouldn’t cost an arm and a leg to maintain in most climates.

Dust and fumes can be a hazard

Wood dust will burn at 500°F or less, and clouds of dust can ignite if they’re exposed to hot surfaces or an open flame. Aside from the fire risk, even relatively minor shop dust encrusting any type of heater will make it less efficient.

There are two types of fuelburning appliances. Opencombustion appliances, such as woodstoves or gas heaters with pilot lights, feed the flame with air from inside the room and are potential ignition sources in dusty environments. Sealedcombustion appliances, such as most direct-vent kerosene heaters and many gas heaters, have no connection between the combustion chamber and the inside air. Rather, a supply duct brings air from outside into the chamber to support the flame. These are safer.

As a practical matter, a woodworker who installs a decent dust-collection system probably will never create enough airborne dust to make the atmosphere truly risky. Most types of heaters should be safe to use in a shop as long as you collect the dust, don’t allow flammable fumes to build up, and clean off the heater on a regular basis. To limit the risk, ask the manufacturer if the surface temperature of the heater will exceed 500°F or if there’s an open flame. It’s a good idea to check with your building inspector and your property insurance agent before you install heat in a shop.

From Fine Woodworking #181

For the full article, download the PDF below:

Comments

Please update this for a future FineWoodworking. I am thinking of a split heat pump for my 32' x 32' shop. Thanks!

Done!... https://www.finewoodworking.com/2017/11/01/265-heating-cooling-shop

Log in or create an account to post a comment.

Sign up Log in