Router Tables

Four favorites, plus two surprises, stand out from a field of 13

Synopsis: One of the most useful tools in the shop, a router becomes even more useful when mounted in a table. So equipped, this valuable tool becomes a mini-shaper that can make small moldings and joints, work with short stock, raise panels for doors, and pattern rout. Contributing editor Roland Johnson evaluated 13 router tables, comparing the sturdiness of their tops and fences, dust collection, and ease of operation and setup.

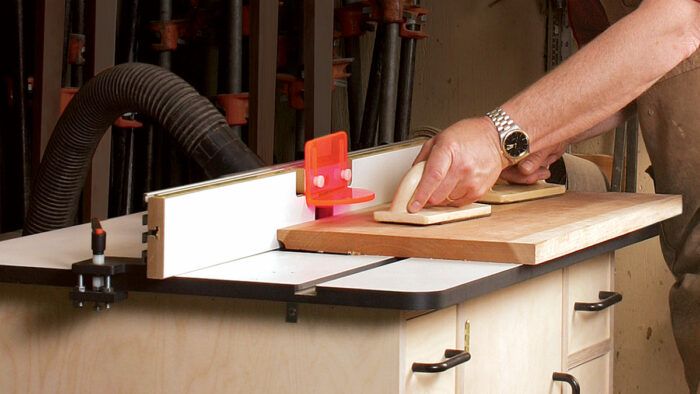

Routers have become one of the most useful power tools in the woodshop. Mounted in a table, the router becomes a mini-shaper that easily can make small moldings and joints, work with short stock, safely raise panels for doors, and pattern rout (shape wood using a template that rides along a bearingguided bit). Most bit manufacturers recommend using large panel-raising bits or molding bits only in a table-mounted router because the bite a large bit takes makes it dangerous to use in a handheld router.

I evaluated 13 router tables for the sturdiness of their tables and fences, dust collection, and ease of operation and setup. All will do the jobs listed. Six stood out as exceptional, and are discussed in greater depth.

Tabletops must be flat and strong

The tops of router tables should be rigid enough to stay flat, strong enough to anchor the fence, and large enough to support panels and wide stock. Three materials are commonly used for tops, and two are very reliable. Phenolic-plastic tops can be relatively thin yet extremely rigid. Steel or cast iron make stout tabletops.

Medium-density fiberboard (MDF) can make a good top, especially when covered with a plastic laminate. But the MDF should be at least an inch thick, or reinforced with steel or aluminum, to resist sagging. I checked all of the tabletops for flatness, and the only tops that sagged were made of MDF. Covering both sides with plastic laminate reduces the chance of warping. Check any MDF top before purchasing or immediately upon delivery to verify that the top is flat.

How flat is flat enough? It depends. If you use your router table to make smaller, flexible moldings, hold-downs will make the stock conform to the table and all will be well. If you do rigid work, such as raised-panel doors, the routed profile will reflect the table’s sag. As a practical matter, I think a sag of greater than 0.030 in. is a problem.

In most cases, the router is fitted to the table via a removable plate that rests in the tabletop. The plate adjusts flush to the top with screws or shims. The screws were easier to use, but since you level the plate with the top at the initial setup only, I didn’t give much weight to this detail. Unless you have a very odd router, all of these tables will work with your existing router. I tried them out with my Porter-Cable 890, which adjusts up and down with a T-wrench inserted through the base.

Six of them stood out as exceptional: the JessEm 03140, Hart Design 46603C, Woodhaven 8244K, Bench Dog 40-037 ProTop Complete, Hawk 940-0050 Routershop, and Grizzly G0528.

To view the entire article, please click the View PDF button below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

3M Blue Tape

Bosch 12V Trim Router

Log in or create an account to post a comment.

Sign up Log in