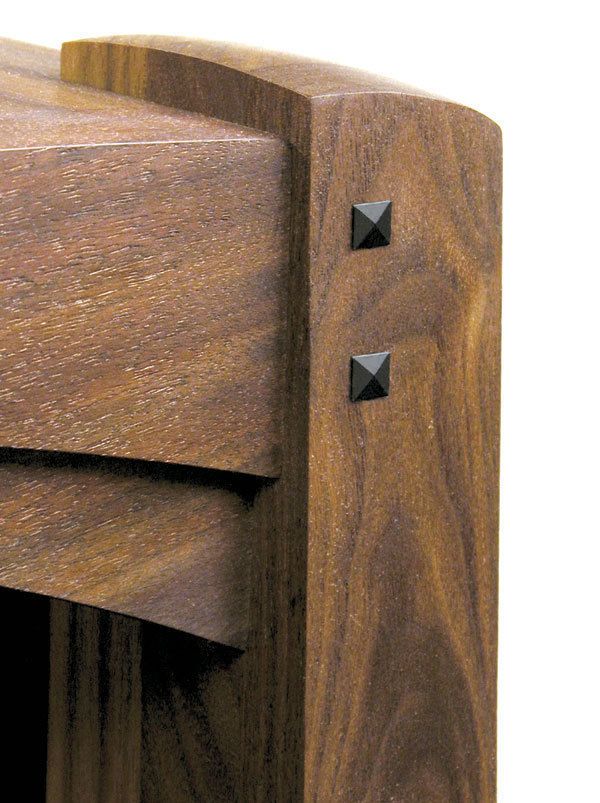

Square Peg in a Round Hole

A streamlined approach to making decorative plugs by the dozens

Synopsis: Roger Heitzman knew there had to be an easier way to install decorative square pegs on a piece of Arts and Crafts furniture than to make countless numbers of round holes and then chop them square. So he devised one: He created a peg with a round stem and a square body. Using a drill press, tablesaw, and bandsaw, Heitzman says he can can produce and install square pegs in a fraction of the time it took to make them the old way, and with more consistent results.

The last time I chopped square holes for decorative pegs, I finished the task with a sigh of resignation and a silent lament: “there must be an easier way.” that was years ago, and after I again went and designed almost 50 such pegs into several arts-and-Crafts-style pieces for a client, my first thought was, “ok, wise guy, now what?” My second thought was to use this opportunity to find that easier way to make and install this attractive detail.

There are three steps in the traditional method of making decorative pegs: Bore the holes and make them square, fabricate the pegs, and dress the exposed ends. I wanted to streamline all three operations.

The first step was to eliminate the repetitive chore of striking a round hole square. that meant I had to find a way to create a round stem on a square body. the plug cutter came immediately to mind. My plug cutters all had sharp-angled shoulders, unsuitable for this use, so I took a 1⁄4-in. plug cutter to my grinder to reduce the shoulder bevel to a more practical, almost square, angle.

Armed with a suitable cutting tool, I was left to decide whether to cut the stem on pre-squared stock or to cut the squares after drilling the stems. a few trials left little doubt that the required precision and speed would come only from cutting the squares after drilling the stems.

Using my drill press, tablesaw, and bandsaw, I was able to produce and install the pegs in a fraction of the time it took to make them the old way, and with more consistent results.

From Fine Woodworking #185

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Drafting Tools

Drafting Tools

Compass

Log in or create an account to post a comment.

Sign up Log in