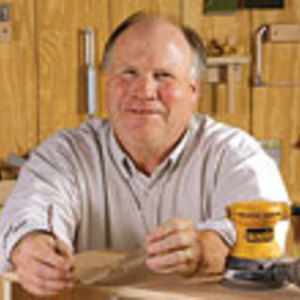

Lie-Nielsen at 25

Woodworking entrepreneur rekindled an interest in serious hand tools

Synopsis: Tom Lie-Nielsen started his business in 1981, making a single model of bronze edge-plane on his kitchen table. Today, some 70 employees at Lie-Nielsen Toolworks make than 50 high-end planes, plus dovetail saws, tenon saws, chisels, and workbenches. Tom Lie-Nielsen sits down with Fine Woodworking on his company’s 25th anniversary to talk about the business of making hand tools.

In 1981, Tom Lie-Nielsen had a fledgling business making a single model of a bronze edge-plane, doing the assembly work on his kitchen table. This year, the company’s 25th, Lie-Nielsen Toolworks makes more than 100 models of high-end hand tools. I recently toured the factory and talked to Lie-Nielsen about the evolution of his company and of hand-tool use over the last few decades. “My father had a wooden-boat-building shop in Maine where we had a small machine shop and made all the hardware for the boats—custom hardware, mostly out of brass and bronze,” he said. It was in that shop, while still in grade school, that LieNielsen developed an appreciation for hand tools.

In 1977, not long out of college, he got his first job. At GarrettWade, a newly created woodworking retailer in New York City, he handled purchasing, importing, customer service, and showroom/telephone sales. It was there that he recognized a need for top-quality, American-made handplanes. Power tools were doing much of the work once done by hand. The major plane manufacturers were shrinking their product lines in response to a smaller market.

“Every year it was obvious where (big manufacturers) were headed, and it wasn’t toward the hand-tool market,” Lie-Nielsen said, adding that customers who wanted a discontinued plane had one option: “Find an antique and fix it.”

A few cottage-industry manufacturers were still making specialty planes for GarrettWade, many of wonderful quality, but these small makers couldn’t deliver on time. Customers wanted the tools, Lie-Nielsen said, but GarrettWade had back-orders all the time. “I couldn’t understand why you couldn’t make tools in a serious way and have them available for people to buy.”

1981: The first plane

One supplier made a handsome and functional bronze edge-plane (based on the earlier Stanley No. 95), most commonly used to square the edge of a board to its face. When the supplier lost interest in making the plane, the young Lie-Nielsen felt the time just might be right for a new plane-maker, albeit one with a single product. He arranged to buy the bronze edge-plane business, including all the necessary tooling patterns and some tutoring sessions. He’d have Garrett¬Wade as a likely customer. And the connections he had made while there would be another plus.

He soon moved to West Rockport, Maine, buying property that included a “very decrepit old farmhouse,” 50 acres of blueberry bushes, and an old woodshed that became the shop. A nearby artisan with a small bronze foundry produced the body castings. The blades were purchased, the parts farmed out to a few local machinists.

From Fine Woodworking #188

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Veritas Micro-Adjust Wheel Marking Gauge

Olfa Knife

Log in or create an account to post a comment.

Sign up Log in