Wiring a Garage Workshop

Plan smart, and you’ll know what to tell the electrician

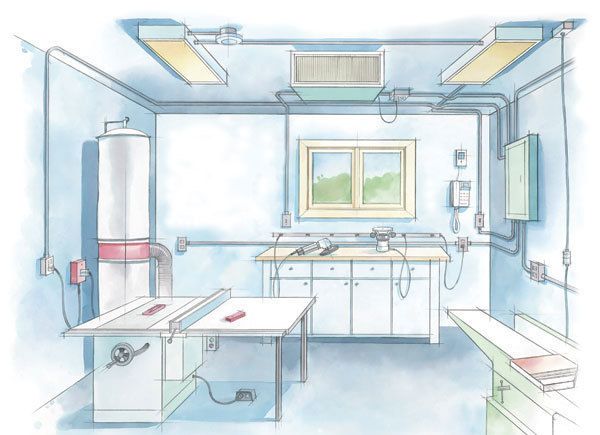

Synopsis: The electrical wiring, outlets, and lighting in your workshop should be as specialized as your tools. Electrician and hobbyist woodworker Clifford Popejoy shares an insider’s view of the special power needs of the woodshop and explains the best way to communicate those needs to your electrician. Tips include installing a dedicated subpanel for the shop, effective woodshop lighting, providing enough power outlets for portable tools; getting plenty of juice to stationary machines; and adding custom touches to improve safety and convenience.

The electrical wiring, outlets, and lighting in your shop should be as specialized as your tools. It’s hard to turn out high-quality work— or to work safely—in a poorly illuminated shop. It is equally frustrating and potentially dangerous if your tools keep tripping breakers on underpowered circuits or if your floor is a tangle of extension cords. To upgrade your workspace to meet the special needs of woodworking, you should know how to identify your needs and then communicate them to an electrician with the skills to turn your plan into reality. If you put these ideas to use, your woodworking will be safer and more satisfying.

Shop features dictate the wiring layout

Installing the wiring for a woodshop is done most easily during construction or remodeling with the walls open, but it can be done anytime. If the walls are closed in, either have the wiring run in surface-mounted conduit or hire an “old work” electrician who can run wires in existing walls and make a minimum of holes to be patched later.

To feed the shop circuits, the best approach is to install an electrical subpanel (breaker box) specifically for the shop. In a well-designed system a breaker will rarely trip, but if it does, it helps to have the panel nearby. There’s a wide range of subpanels available, and your choice will depend on how much power and how many circuits you need.

At any given time, most one-person shops will be running one major stationary tool, a dust collector, an air filtration system, and lights. In this case, 60 amps at 240/120v likely will provide enough power. If there’s heating or air conditioning running as well, a 100-amp subpanel probably will be adequate. I suggest a panel with room for 16 or 20 circuit breakers. These are starting points. Because each shop is different, you should calculate the number of circuits and power needs of your own.

There are two interdependent aspects to wiring a shop. one is circuit design—how the various things that use power (called “loads”) are arranged and grouped, and how they are connected to their electricity source through wiring and circuit breakers. The other is the choice and location of light fixtures, receptacles, and switches.

From Fine Woodworking #188

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in