All About Frame-and-Panel Construction

Frame-and-panel construction is a popular method for making doors, cabinetry, and a variety of furniture and architectural components. Its primary purpose is to create a large panel with minimal wood movement. Whereas solid wood shrinks and expands with changes in humidity affecting its overall dimensions, a frame and panel doesn’t. Instead, the panel is able to expand and contract freely inside a unchanged frame.

The Basics:

– Anatomy: Just like the name suggests, this construction method consists of a panel that fits inside a frame

– Styles vary: A panel can be raised, flat, or decorated with molding

– Methods of Construction: Frames typically are constructed with mortise and tenon joinery, though there are a variety of modern methods

– Uses: Doors, case pieces (chests of drawers and bookshelves), wainscot paneling

Anatomy of the frame and panel

Scarcely another system in the whole range of woodworking has more variation and broader application than the frame and panel. In the frame-and-panel system, pieces of solid wood are joined together into a structure whose overall dimensions do not change. This is vastly different than a single solid panel of the same size, which will shrink and expand with changes in humidity.

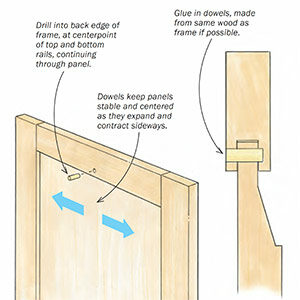

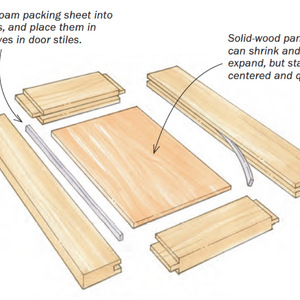

The frame is usually rectangular, mortised and tenoned together, with a groove cut into its inside edge. The panel fits into this groove: tightly on its ends since wood does not move much in length, but with room to spare on the sides because wood moves most in width. Wood is not uniform and as it moves in response to changing moisture conditions, it cups, twists, springs and bows. Trapping the panel in the groove inhibits this misbehavior.

Making a frame and panel

There are a variety of ways to produce a frame and panel. Beginning with the frame, the classic method is with some variation of mortise and tenon joinery. However, modern methods include cope-and-stick router bits and pocket-hole joinery.

Historically, the panel is made of solid wood. However, sheet goods are often used in modern construction to cut down on the cost and complexity of construction. It fits inside a groove cut along the inner edge of the frame, typically with a

There are almost as many ways to cut raised panels as there are tools in the woodshop. The shaper may be the most efficient, but if you don’t own one, a number of other methods will work from hand planes to the router table to the tablesaw. Typically, those methods that use power tools require building a jig to support the panel while a bevel is cut around all four sides.

Uses for the frame and panel

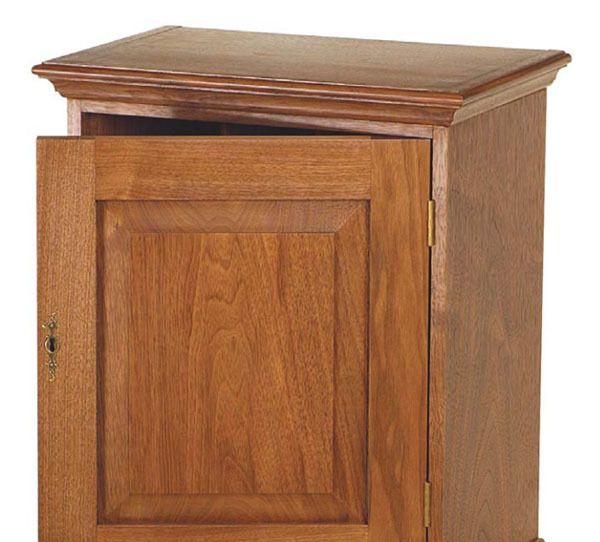

The most common use for a frame and panel is a cabinet door or full-size door. However, the construction method is also ideal for building furniture pieces including bookshelves and chests of drawers.

Fine Woodworking Recommended Products

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Estwing Dead-Blow Mallet

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in