Shaping a Bench Seat

Q:

I’m making a couple of hallway benches with shaped seats for a local school, but I can’t figure out how to make a wide cove across the length of the seat plank.

JHMurphy, via Ask the Experts, None

A:

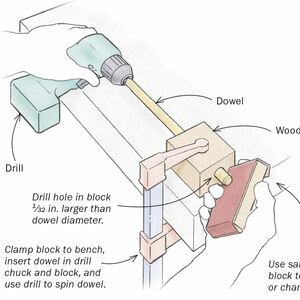

I’d use a tablesaw to cut the cove along the length of the seat (see drawing right). Set the saw up with a dado set with all of the cutters in it so you are taking a wide cut down the length of the seat blank. Now, by changing the blade height, the blade angle, and the fence position, you can work your way across the seat in a dozen or so passes that will remove 95% of the wood. If your saw doesn’t have a lot of power, you may have to make the deepest cuts in two or three steps, raising the blade higher for each pass.

I’d use a tablesaw to cut the cove along the length of the seat (see drawing right). Set the saw up with a dado set with all of the cutters in it so you are taking a wide cut down the length of the seat blank. Now, by changing the blade height, the blade angle, and the fence position, you can work your way across the seat in a dozen or so passes that will remove 95% of the wood. If your saw doesn’t have a lot of power, you may have to make the deepest cuts in two or three steps, raising the blade higher for each pass.

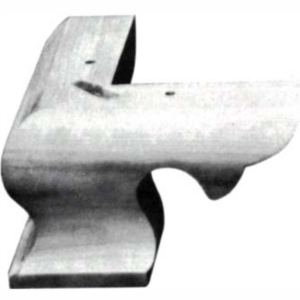

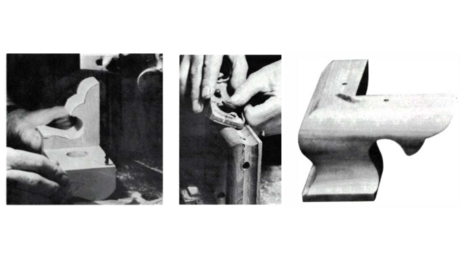

Once the bulk of the material is hogged out, you can smooth the surface to your final shape with scrapers, sandpaper, a compass plane, a spokeshave with a curved sole, or any combination of the above.

Setting the blade

Setting the blade

To set the blade for each pass with the tablesaw, make a template from plywood or cardboard. This arch-shaped template will be a two-dimensional cross-section of the cove you’re hogging out. Place the template on the saw table and then adjust the settings so that the blade just touches the inside surface of the template. Mark the blade’s position on the template before you put it aside so you will know where to move on the template for the next pass.

Safety first

A safety concern with this whole operation is that you might push the blank from its back edge and have your fingers in line with the tablesaw blade when it comes out through the back edge of the blank. I would screw short length of 2×4 crosswise onto the top face of blank, just a couple of inches in from the trailing end, so you will have a safe place to push against. The screw holes will be on the underside of the finished seat so they won’t be visible. Be sure the screws don’t end up projecting into the area you are cutting.

If the seat blank is heavy, use infeed and outfeed supports to keep control of the wood. Waxing the table and the fence will make sliding the heavy blank easier. A feather board on the side wouldn’t do any harm but it isn’t a necessity.

Photos: Gina Eide

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in