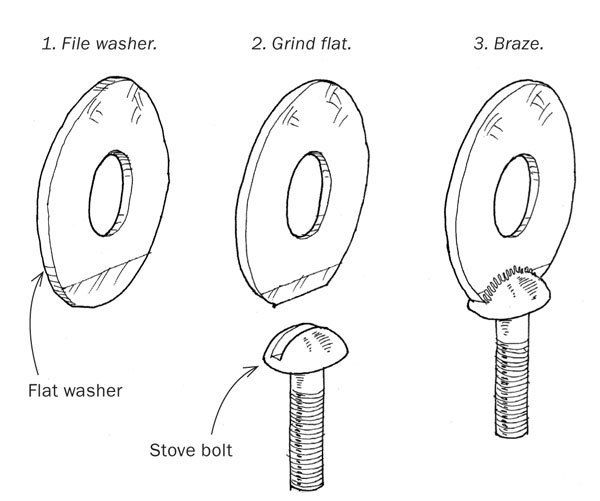

My jigs often have adjustable parts. To lock them in place, I use a thumbscrew made from a stove bolt (also called a round-head machine screw) and a flat washer. The thumbscrew is so sturdy that you can place a rod or screwdriver through the washer for leverage.

File the sides of the washer to fit in the bolt slot. Also, file a flat on the circumference of the washer where it fits into the slot. Then, with the washer in the slot, use a propane torch and silver braze rod (also called silver solder) to join the parts permanently.

To protect the bolt threads while brazing, thread a nut onto the bolt and tighten it up to the head. Then, with the nut as a holding point, clamp the bolt in a machinist’s vise. After applying flux and brazing the parts, remove the nut from the bolt. This cleans any residual flux and oxide away from the bolt threads.

Clean the joint with a rotating steel brush. If you want it to look especially good, add one more step and polish it to a high shine.

Drawings by Jim Richey.

Drawings by Jim Richey.

Fine Woodworking Recommended Products

Hedgehog featherboards

Double Sided Tape

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in