Choosing and Using Casters

What casters work best in which workshop applications, and how to build two versatile rolling bases

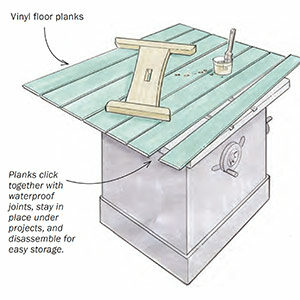

Synopsis: Whether they are used to hold stationary power tools, store lumber, or serve as a work table, rolling platforms and cabinets help to free up shop space and let you configure your shop differently for different jobs. But when it comes to choosing the right casters for these platforms and mounting them correctly, it helps to have a little advice. Fine Woodworking shop manager John White gives expert tips on choosing the right type of wheel, which applications benefit from fixed, swivel, and braking casters, and what size casters work best for different jobs. He also provides plans for a torsion-box platform base that can be used to support furniture, assembly tables, tool carts, floor-standing machines, clamp racks, and sheet-good racks; and a cabinet-style base that will provide storage and support for bench-mounted tools such as thickness planers, drill presses, and miter saws.

From Fine Woodworking #190

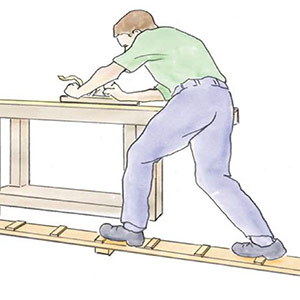

Small shop or large, most woodworkers find it makes sense to put some machines and fixtures on wheels. Whether it carries a benchtop planer, a worktable, or a wood rack, a rolling workstation not only frees up space; it helps you line up your tools—and your materials—more efficiently for specific jobs.

However, if you’re like me, you know these little wheels can also cause big problems. They can leave a power tool restless, fidgeting when you want it to stand still. Poorly designed or poorly loaded, they can make their cargo tippy. They can stop on a dime—or a sliver of wood—while you’re gliding from A to B; and they can wreak havoc on your shop’s new hardwood floor.

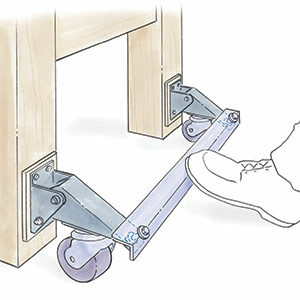

So how do you get the most out of a set of casters? Simple. Choose the right ones for the job at hand, and mount them properly on the base of the tool or fixture they support. Casters come in a wide variety of sizes and styles, but for most workshop applications you need only consider those most commonly offered in woodworking catalogs. Here’s what you should know.

Key factors: rolling, steering, stopping You’ll find casters with a range of tire materials, from soft rubber to rock-hard steel or plastic wheels. My advice is to stick with Mr. In-Between: urethane. It’s the same material used for skateboard wheels. Tires made of this synthetic material have enough “give” to climb over wood chips; they have a good load capacity for their size and cost; they’re stable; and they hold up well.

Bigger is better— Although they are pricier, larger wheels roll easier and can handle more weight. I’ve found that any wheel under 4 in. dia. catches too easily on cracks or seams in a floor, or on the small wood chips and even sawdust that always seem to be underfoot. For most applications, a 4-in. or 5-in. wheel will work well, although you may need to go to a larger diameter to handle very heavy items, like a lumber rack. If your shop floor is plywood or hardwood, choose larger-diameter and wider wheels to prevent floor damage.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey EKH Trigger Clamps

Starrett 12-in. combination square

Veritas Standard Wheel Marking Gauge

Log in or create an account to post a comment.

Sign up Log in