Festool - Domino Joiner

New joining system cuts mortises to use with prefabricated slip tenons in five different sizes

True innovations in portable power tools are rare. The random-orbit sander, the biscuit joiner, cordless technology-the big leaps forward are few and far between. Festool, a German company, stands out in recent years for reinventing a number of old faithful tools. Readers will recall the plunge-style circular saw with the ingenious guide track, as well as a high-end cordless drill that accepts three different heads.

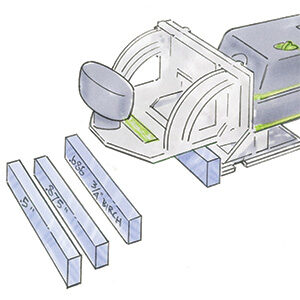

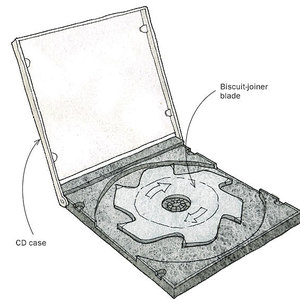

Festool’s latest innovation-the Domino Joiner-may be the company’s most significant. Available in April, this tool looks and operates like a biscuit joiner, but the Domino uses a spinning and oscillating (wobbling side to side) bit to cut a full mortise in a single plunge. The system employs different-size beech slip tenons. Though the largest tenons are only 3/8 in. thick by 7/8 in. wide by 2 in. long, the uniformly machined mortises and perfect-fitting tenons added up to very strong joints-strong enough for cabinet doors, drawers, face frames, many chairs, and all tables just shy of dining size.

But the real sizzle here is speed. I assembled an entire table, with two slip tenons at each joint (32 mortises in all), in about half an hour, with perfect alignment of parts. I can’t think of a way to do this faster with the same strength and results-not even close.

The downside for some woodworkers will be the price, estimated at $700 for the basic kit with one 5mm-dia. cutter, and another $200 for a starter kit that includes all four of the carbide-tipped cutters (5mm through 10mm) and more than 1,000 beech tenons in various sizes. Adjustments are a joy on this tool. Settings for depth and width of cut (oscillation) are precise and easy. As with a biscuit joiner, you reference off a movable front fence to get different slot locations and angles. The Festool’s movable fence is nicely designed, but we had two problems with it. One of its pivot pins dropped out, and had to be reinserted and tightened. Worse, though, part of the clamping mechanism broke. With lots of people using the tool, we can’t say for sure that it wasn’t user error, but a close examination of the break reveals a thin cast section that must withstand considerable pressure if someone overtightens the fence. Festool replaced the front half of the machine, and there have been no problems since. Bottom line: Don’t overtighten the clamp handles on the fence; they don’t require much pressure.

I have only two other quibbles with the tool. While it oscillates to three mortise widths-up to 11/4 in. wide-tenons come only in the narrowest width. The extra room eases assembly when the mortises are used in rows, but Festool is missing an opportunity to provide more substantial tenons. Also, alignment pins in the front that reference off the corner of a workpiece to make layout unnecessary are too far from the edge of the mortise for my liking, leaving room for twist at the corner of a frame, for example.

Chairmakers will like the accessory that supports narrow parts to allow end-grain mortises at various angles.

Dust collection is critical with this tool; the airflow keeps the motor cool and clears the chips so that the cutter doesn’t bind in a deep slot. Also, clamp the workpiece, hold the unit down firmly, and let the tool cut. You’ll need to plunge slowly into the hardest woods.

Overall, the Domino is an impressive tool that could change your woodworking. For more information, visit www.festoolusa.com.

Fine Woodworking Recommended Products

Festool Rotex FEQ-Plus Random Orbital Sander

Festool Cleantec CT 26 E HEPA Dust Extractor

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in