Left Tilt vs. Right Tilt Table Saws

What's The Difference: Both styles have pluses and minuses relating to safety and accuracy

Although most tablesaws sold in the United States today have a left tilt blade for cutting bevels, some saws are still sold with right tilt blades. You’ll hear many viewpoints on which kind of saw is better, and as with most debates, both sides have some valid points.

Measuring is easier on right tilt saws

On a right tilt saw, the arbor that holds the blade comes from the right side. This has several advantages. For one, the scale on the rip fence always reads the distance accurately between the fence and the right side of blade, whether it is a thin-kerf blade or a dado set.

For optimum safety, the right side of a blade guard’s splitter should be set tight to the actual cut line. This assumes you are using the fence to the right of the blade. With a right tilt saw, blade thickness changes don’t alter this alignment, and the splitter remains in the safest possible position for all cuts.

The main disadvantage of a right tilt saw is that beveled ripcuts can be more dangerous with the fence to the right of the blade. The offcut can ride up the blade’s rear teeth, or the workpiece can get trapped under an angled blade, potentially causing a severe kickback. Also, the opposite bevel gets wedged under the rip fence. You can make beveled ripcuts with the fence to the left of the blade, but some people find the stance awkward and the table support inadequate.

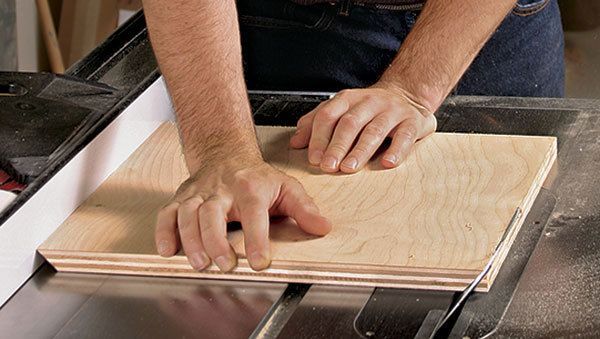

Left tilt miters. A left-tilt saw, with the fence to the right of the blade, is the safest arrangement for cutting miters (above).

Right tilt miters. To avoid trapping the workpiece under the blade on a right-tilt saw (above), move the fence to the left side of the blade (below).

Bevel cuts are safer on left tilt saws

In general, the pros and cons of a right tilt saw are reversed for a left tilt one. With a left tilt saw, the arbor comes from the left, so changing blade thicknesses leads to a loss of fence-tape accuracy. Second, the right side of the splitter won’t be at its ideal safety setting for varying blade thicknesses. If you set the splitter tight to the right side of a full-kerf cut line and then install a thin-kerf blade, the workpiece will hit the front of the splitter and get stuck. The best solution is to buy splitters and blades of the same thickness, especially for ripping.

Left tilt dadoes. On a left tilt saw, because the arbor comes from the left, the fence tape is not accurate with blades of different thicknesses.

The left tilt saw wins out when making beveled ripcuts with the fence to the right of the blade. The workpiece is not trapped under the spinning blade and the offcut is free to slide off to the left. When choosing a saw, consider your work habits. Above all, work safely and use a splitter whenever possible.

Photos: Mark Schofield; drawings: John Tetreault

From Fine Woodworking #191

More from FineWoodworking.com:

- Tool Test: Hybrid Tablesaws

- Tool Test: 10-in Cabinet Saws

- Tool Test: Cabinet Saws for the Home Shop

- Tool Test: 9 Midsize Tablesaws

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Veritas Precision Square

JessEm Mite-R Excel II Miter Gauge

Log in or create an account to post a comment.

Sign up Log in