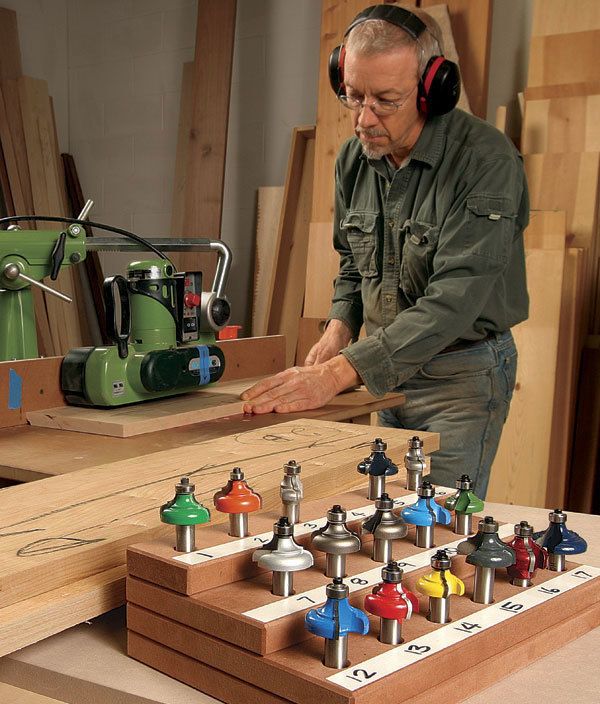

Tool Test: Router Bits

We torture-test 18 profile bits to find the smoothest cutters

Synopsis: As woodworkers, we ask two simple things of our router bits: Cut cleanly, and stay sharp. But with so many companies manufacturing bits, it isn’t always easy to identify the top performers. Associate editor Tom Begnal purchased the same style carbide-tipped cove-and-bead bit from 18 manufacturers and put each one to the test. Used in a router table, each bit made an extensive series of test cuts on edge grain, end grain, and premium and standard MDF. Afterward, the results were rated independently by Fine Woodworking editors. A bit was rated “excellent” if the molding it produced required little to no sanding.

Products tested include: Amana 54134; BC Saw 43272; Bosch 85605M; CMT 844.850.11; Eagle 171-2605; Freud 38-614; Grizzly C1755; Holbren 24229; Infinity 44-850; Lee Valley 16J34.52; MLCS 8788; Porter-Cable 43179PC; Ridge 23-515; Rockler 91680; Southeast SE3212; Whiteside 3212; Woodline WL-1253; Woodtek 820-228.

Woodworkers want a router bit to do just two things: cut cleanly and stay sharp a long time. But with a long list of companies selling bits, it’s hard to identify the top-of-the-line performers. So to find out how bits measure up when it comes to smoothness and longevity, we purchased the same-style bit from 18 companies and tested the lot.

The bit goes by several names. Commonly called a cove-andbead bit, it also can be labeled a bead-and-cove bit, a roundingover cove bit, or a classical bit. We chose that bit because it cuts two profiles, a cove and a bead, with a shallow step in between. as a result, we could evaluate the bit’s ability to make a concave cut, a convex cut, and two sharp corners.

Our goal was to use carbide-tipped bits with a 1⁄4-in. radius on both the cove and the bead. However, we soon learned that some are available only with a radius of 3⁄16 in., or a combination of 3⁄16 in. and 1⁄4 in. So, with one exception, all the bits we tested have cove and bead radii that range from 1⁄4 in. to 3⁄16 in. The Holbren bit is the exception, as it creates a 1⁄4-in. cove and a 3⁄8-in. bead. However, we did not see a significant correlation between size of bit and test results. also, we tested only bits with 1⁄2-in.-dia. shanks.

How we tested the bits

The tests were done on a rock-solid router table with a massive fence made specifically for the test. a sturdy 31⁄4-hp fixed-base router provided the get-up-and-go. a power-feeder ensured that the test stock was fed through each bit at a constant rate of 5 ft. per minute (fpm), a speed that mimicked our typical hand-feed rate. each bit was tested with the fence in line with the bearing, so the bit would make a full cut.

The test was designed to include a number of materials, feed rates, and grain orientations, as well as performance after a few hundred feet of wear. First, we made edge-grain cuts on 30-in. lengths of knot-free sugar maple, black cherry, red oak, and eastern white pine, four woods that offer a mix of hardness and cutting characteristics. We also made end-grain cuts on 6-in.-wide sections of the same woods.

From Fine Woodworking #191

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Craftsman Random Orbit Sander

Milwaukee M12 23-Gauge Cordless Pin Nailer

Bosch 12V Trim Router

Log in or create an account to post a comment.

Sign up Log in