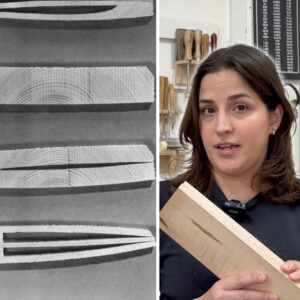

How To Dry Lumber

A seasoned sawyer reveals his secrets for drying lumber in a kiln or in the open airLearn the secrets to drying lumber in this video hosted by author and furniture maker Mario Rodriguez. We traveled to Worcester, Penn., to the mini mill of Dave and Carol Spacht, for a comprehensive overview of the drying process. The video explains how a kiln works, how to build your own kiln for kiln drying lumber, how to air dry lumber, in addition to a handful of tips on how to dry wood that only a seasoned sawyer can reveal.

More in this series

Additional Reading

- Dry Your Own Lumber

- Air-Drying Lumber

- Seasoned Wood: What You Need to Know

- Building a Solar Kiln

- Drying Freshly Cut Lumber

- Drying Small Parts in Your Oven

- Using a Portable Bandsaw Mill

Comments

A good video on drying lumber which I hadn't seen before. I'd like to pass along my solution I came up with to use in the high desert of eastern Oregon. When I began milling lumber after a big fire here, I quickly realized I needed to dry it better than just air dry. I looked at several kiln designs I could make before running into an article which mentioned using a greenhouse. I already owned two which were 12x24 and I hadn't set up yet after moving from California.

I poured a concrete slab after placing plastic underneath to prevent moisture migration and set up a greenhouse with doors on both ends where the prevailing wind can blow thru it. I get a lot of good hardwood from tree trimmers in town, along with pine and fir logs from the mountains around me. I do much the same as explained in the video: I coat log ends right away to limit checking and have the board ends already sealed before they go in the kiln.

My boards normally go straight from the mill to the kiln and are stickered as they go in. With green wood, I leave the doors open perhaps a week, plus may add a fan, if the wind isn't blowing enough. Once the wood gets rid of enough surface moisture, I can start closing the doors. The sun manages to heat it to between 120-140 during the day while it cools down to 50-70 at night, before doing it again the next day. Usually, there is enough air leakage to get rid of the moisture, if not, I can open the doors a bit. This has proved very good at slowly drying the wood to 8-10% while limiting cupping and warp even on notorious species like our Siberian Elm here. I'm not spending any money heating the kiln, yet also get it hot enough to kill off the boring insects which are otherwise still alive in air-dried lumber a year or two later. This has proved both low cost to build and operate for me.

Log in or create an account to post a comment.

Sign up Log in