Is It Time to Get a Fresh Edge?

Signs that your tools are losing their cutting power

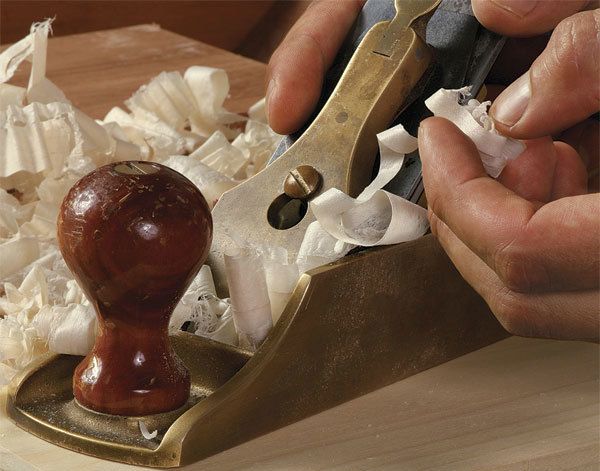

Synopsis: It takes practice to know when your tools need sharpening. But for both hand and power cutting tools, the warning signs are similar: It takes more effort to cut wood and to control the tool while you’re doing it; the results are below par, with telltale signs such as burning, a dull surface, or tearout; and the edge of the blade itself shows signs of wear. Several of Fine Woodworking‘s contributing editors weigh in with advice on how they determine it’s time to stop cutting wood and start sharpening tools.

Beginning woodworkers are told often about the importance of keeping tools sharp. Deciding when to stop and resharpen or replace a tool ultimately depends on how much poor performance you’re willing to accept. Applying that lesson, however, takes practice. For starters, how can you tell when a tool is losing its edge?

Christian becksvoort calls the descent from sharp to dull “a gentle, downward curve, with steadily declining results and ever more effort required.”

We asked becksvoort and other contributing editors to describe some indicators that it is time to sharpen. the three warning signs: effort, results, and tool condition.

How hard are you working?

When deciding whether a tool is losing its edge, “my first clue is an increase in cutting resistance,” says Garrett Hack.

Simply put, a dull cutting edge on a hand or power tool requires more force to cut the wood. On router tables, for instance, a dull bit means you’ll have to exert more pressure to keep the wood against the fence.

“A dull bit will tend to push the material away,” roland Johnson says. “A sharp bit just cuts.” In similar fashion, a dull jointer knife wants to lift a board off the table.

You’ll have to push harder to move stock through a cut if a bandsaw or tablesaw blade is dull. A dull tablesaw blade requires extra effort even if cleaned of gum and pitch, becksvoort says.

On the bandsaw, you’ll find yourself pushing the blade against the rear thrust bearing as you force stock through a cut, according to Gary rogowski. This is more apparent with thicker stock.

With handplanes, Hack says, a dull edge is most noticeable on end grain. And dull chisels are harder to handle.

“On long grain I have to push harder,” says Hack, “and I sometimes lose control because the dull edge wants to dive into the fibers rather than sever them.”

Becksvoort sharpens his chisels after one large dovetailed case or two or three smaller pieces.

From Fine Woodworking #193

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Rockler Silicone Sharpening Stone Tray

Honing Compound

Wen Diamond Grinding Wheel

Log in or create an account to post a comment.

Sign up Log in