Set Up Shop on a Budget

How to find bargains and work with fewer tools.

Synopsis: Taking issue with Asa Christiana’s recent article, “Set Up Shop for $5,000,” Mike Bielski gives his take on what it should reasonably cost to get started in woodworking. By paring your shop down to the essentials and buying a blend of used and factory reconditioned tools, he says you can cut that startup cost substantially.

This article was inspired by editor Asa Christiana’s piece in last year’s Tools & Shops issue, titled “Set Up Shop for $5,000.”

That headline struck me as discouraging. As an entry fee, $5,000 seems high enough to exclude a number of potential woodworkers, myself included. Christiana softened the blow by saying that used tools could cut the cost roughly in half. That figure seemed much closer to my experience, which involved buying a mix of new and used tools. Having said that, buying the right used tools is much more difficult than buying from a catalog or dealer who stocks everything needed to build a great shop. It requires a bit of guile and a good plan, but the payoff is worth it. Through careful choices and good fortune, I was able to outfit my shop with a blend of new and used tools for around $2,000.

A shopping strategy: foundation before frills

My approach wasn’t about buying cheap tools. Buying on price alone often costs more in the long run when a cheap tool doesn’t perform or fails and must be replaced with one that works. The trick is finding quality tools at an affordable price, and knowing how to make the most of them.

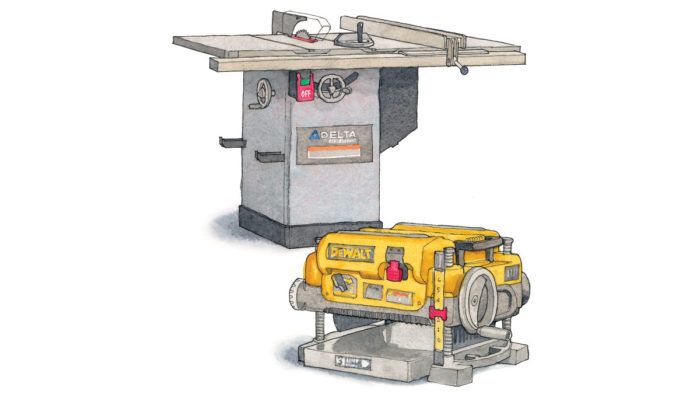

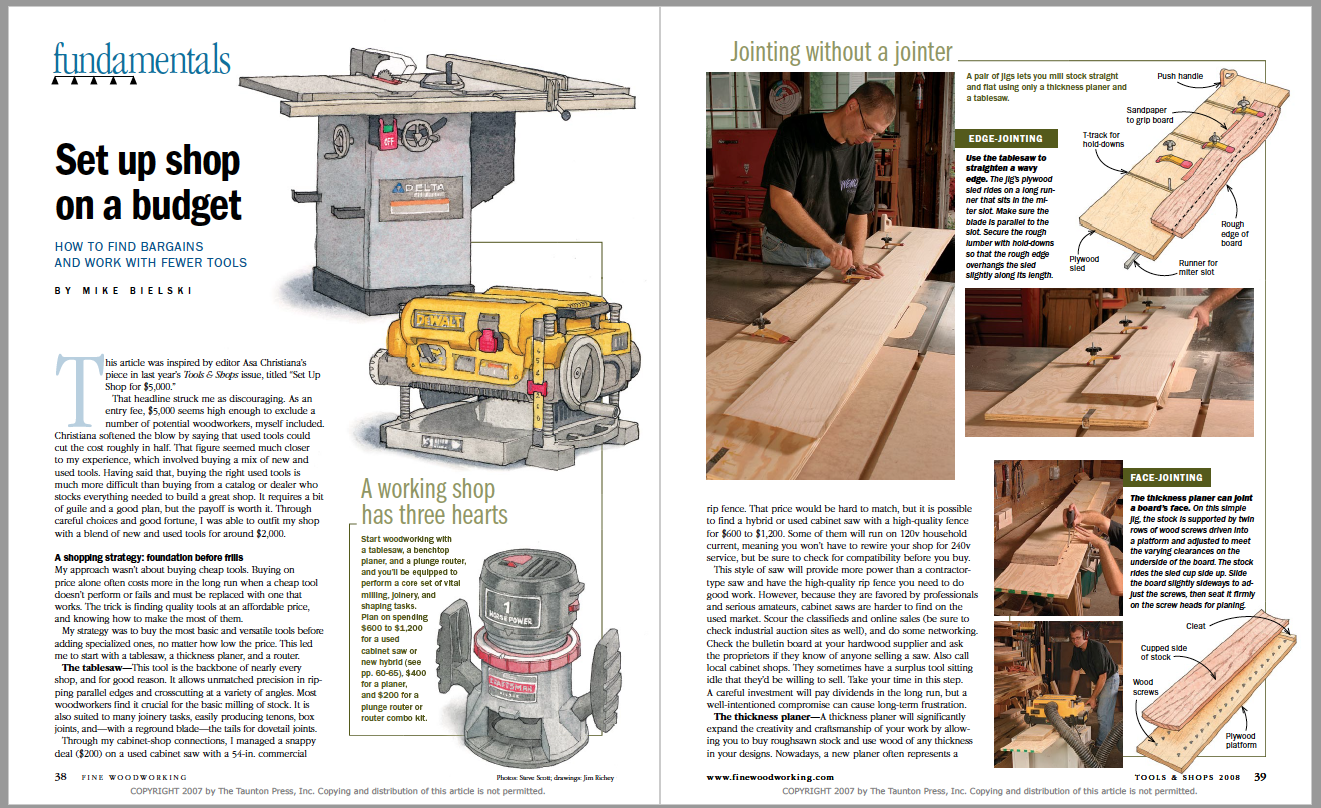

My strategy was to buy the most basic and versatile tools before adding specialized ones, no matter how low the price. This led me to start with a tablesaw, a thickness planer, and a router.

The tablesaw—This tool is the backbone of nearly every shop, and for good reason. It allows unmatched precision in ripping parallel edges and crosscutting at a variety of angles. Most woodworkers find it crucial for the basic milling of stock. It is also suited to many joinery tasks, easily producing tenons, box joints, and—with a reground blade—the tails for dovetail joints.

Through my cabinet-shop connections, I managed a snappy deal ($200) on a used cabinet saw with a 54-in. commercial rip fence. That price would be hard to match, but it is possible to find a hybrid or used cabinet saw with a high-quality fence for $600 to $1,200. Some of them will run on 120v household current, meaning you won’t have to rewire your shop for 240v service, but be sure to check for compatibility before you buy.

This style of saw will provide more power than a contractor-type saw and have the high-quality rip fence you need to do good work. However, because they are favored by professionals and serious amateurs, cabinet saws are harder to find on the used market. Scour the classifieds and online sales (be sure to check industrial auction sites as well), and do some networking. Check the bulletin board at your hardwood supplier and ask the proprietors if they know of anyone selling a saw. Also call local cabinet shops. They sometimes have a surplus tool sitting idle that they’d be willing to sell. Take your time in this step. A careful investment will pay dividends in the long run, but a well-intentioned compromise can cause long-term frustration.

From Fine Woodworking #195

From Fine Woodworking #195

For the full article, download the PDF below:

Comments

Lots of good tips in here. It's sure easy to get caught up in a "gotta have that tool" syndrome. Take the time to evaluate what you really need a new tool for, and whether you will use it again.

Log in or create an account to post a comment.

Sign up Log in